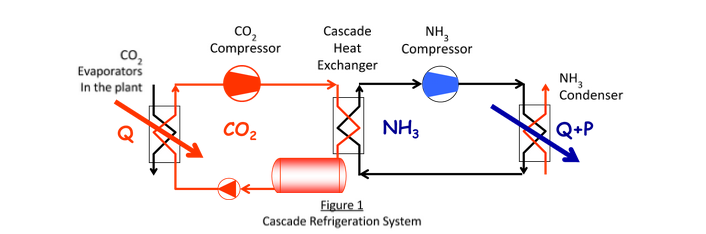

Why CO2 is a Viable Refrigerant Alternative

Did you know CO2 has been used in mechanical systems since the 1800s? However, over time, the industry has gravitated away from CO2 toward lower pressure, synthetic refrigerants like Freon. But now that synthetic refrigerants are being phased out due to their negative environmental impacts, it’s time to take a renewed look at CO2 as a viable refrigerant alternative. Continue Reading “Why CO2 is a Viable Refrigerant Alternative”