[SlideShare] 3 Things to Know About the Changing Refrigeration Climate

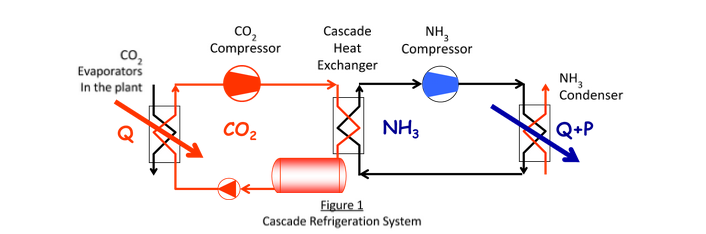

Did you tune in to our Food Engineering webinar last week? We discussed the changing refrigeration climate, including what you should know about revised compliance schedules, innovative refrigeration technologies and the pros and cons for each. You can check out our full presentation in the SlideShare provided below.

Continue Reading “[SlideShare] 3 Things to Know About the Changing Refrigeration Climate”