Refrigeration screw compressors use axial thrust load bearings—and they have a life expectancy that will begin to fail over time. At one time or another, all food processors and beverage manufacturers will be in the market for a refrigeration compressor rebuild or replacement. Because the compressor and its bearings will deteriorate over time, staying on top of its performance is crucial to avoiding a catastrophic failure. Here are three methods that can help gauge your compressor’s fitness.

1. Oil analysis

Take an oil sample from your compressor (downstream of the oil filters), and have it analyzed for impurities and wear properties, per original equipment manufacturer (OEM) guidelines. This is an easy thing to do and the sample can be tested at an independent laboratory that is knowledgeable on the specific parameters for the product or by the OEM.

Typical red flags:

- High iron count (unacceptable range levels vary by product and are typically between 15-20 parts per million)

- Abnormal particle counts (specific to your particular brand of oil)

- High water content (per the Karl Fischer method) (unacceptable range levels vary by product and are typically between 100-150 parts per million)

2. Vibration analysis

For this analysis, an authorized professional collects the data with a certified/calibrated vibration meter and evaluates the compressor’s spectrums.

Typical red flags:

- Bearing defect frequencies

- High acceleration/ velocity values (each OEM has specific values and guidelines)

3. Bearing end play measurement

This is when a service professional measures the amount of wear movement within the bearing. This is measured in thousandths of an inch with a certified/calibrated dial indicator. Take these measurements when the machine is hot, or at operating temperature. Different types of bearings require different test procedures—follow OEM guidelines for their compressors.

Typical red flags:

-

Wear movement as low as one thousandths or as high as five thousandths, based on your bearing manufacturer

Be sure to incorporate the above measures into your predictive maintenance program. Each of the methods should be performed on a routine, scheduled basis, at least twice a year for vibration and oil analysis and once a year for bearing end play. This will establish trends to help analyze your compressor’s fitness and performance.

While an oil analysis is a great, low-cost way to determine wear properties affecting your compressor’s fitness, give more weight to your vibration analysis and bearing end play measurements. These are stronger indicators of compressor fitness. For example, if you had an oil analysis that showed a high iron count but the vibration analysis and bearing end play measurement were normal, you should not replace or rebuild your compressor based solely on the oil analysis results. A better and more prudent approach would be to monitor the machine more frequently and to take another oil sample.

Compressor rebuild vs. replacement

After performing the above three tests, it may become clear it’s time to either rebuild or replace your refrigeration compressor. How do you know which option to go with? It’s up to you.

Rebuild pros and cons

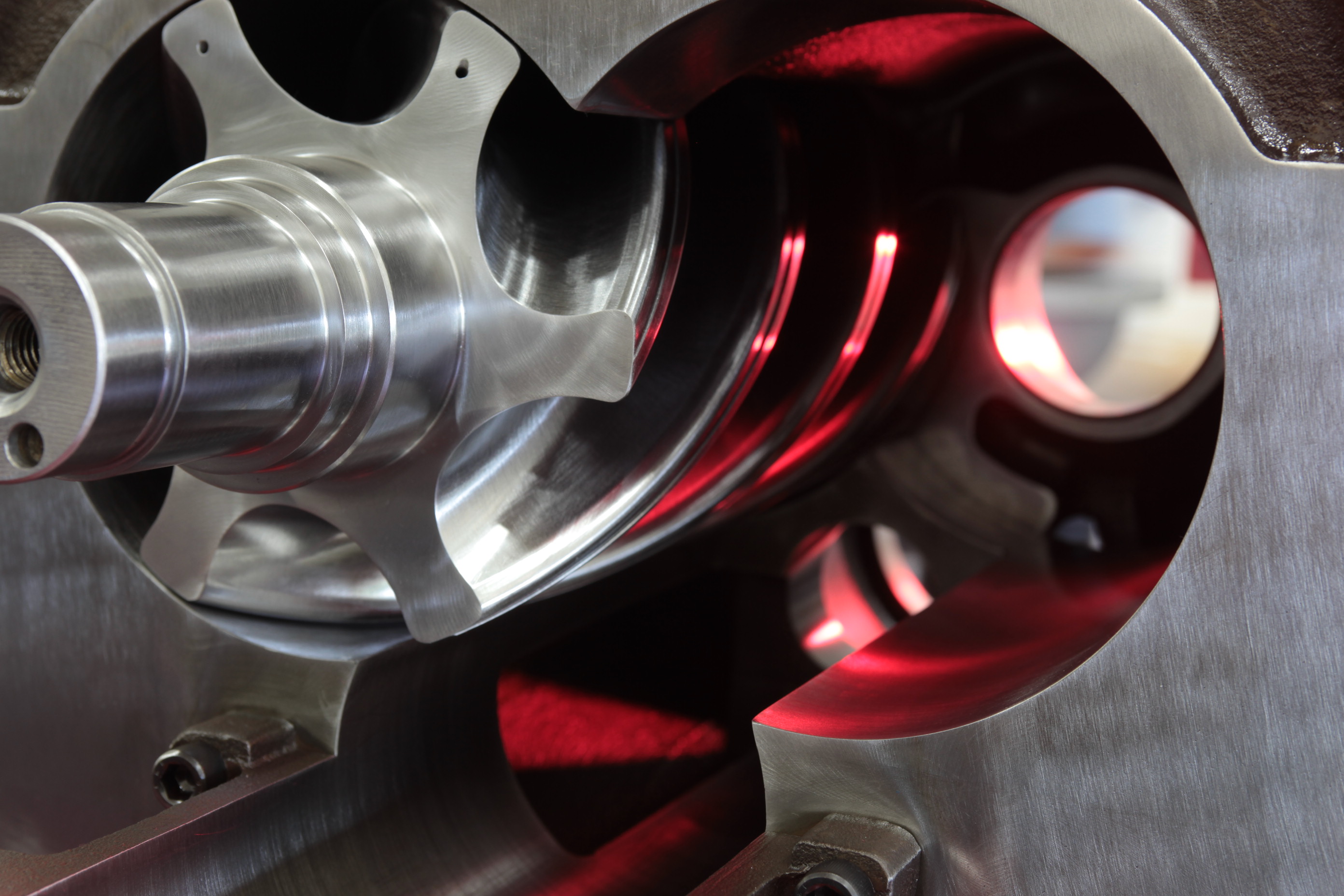

A compressor rebuild involves a complete disassembly and precision measurement of all critical areas. The assembly also encompasses setting all critical dimensions and levels to OEM specifications, tolerances and procedures. A rebuild is a lower cost alternative to a replacement; however, it requires more down time. It depends, but the rebuild process usually takes about a week.

Replacement pros and cons

If you can’t afford to have your compressor offline for several days, a replacement may be a better option, though it is more expensive. Replacements are either a remanufactured or new compressor. Remanufactured compressors may be supplied by qualified and knowledgeable rebuilders or by the OEM. When replacing a compressor, you must ensure the replacement will be a suitable match to the existing compressor—pay close attention to detail during this process. There are many variables within the same model line that can adversely affect the performance and operation when applied incorrectly, such as:

- Internal Vi’s

- Liquid injection angles

- Pressure-specific connections

The same strict adherence to OEM rebuilding procedures and guidelines must be followed in the remanufacturing process, as well.

Best practices for both

If you do opt for a compressor rebuild or remanufactured replacement, ensure that your provider is OEM qualified. Your provider should have the capabilities and knowledge to follow all OEM guidelines/tolerances and have the required “special” tooling for your particular brand of compressor to install the precision bearings for proper life expectancy and performance and to be able to balance the rotors.

Additionally, the use of a clean climate control facility enables the compressor to be precisely reset to the OEM clearances and protects the precision internal components. Some organizations may be equipped to solely change out parts of the compressors—not remanufacture the entire piece to a “like new” condition in a controlled environment exclusively for the rebuilding and remanufacturing of compressors.

If you’d like to learn more about refrigeration compressor rebuilds and replacements, email me at foodforthought@stellar.net.