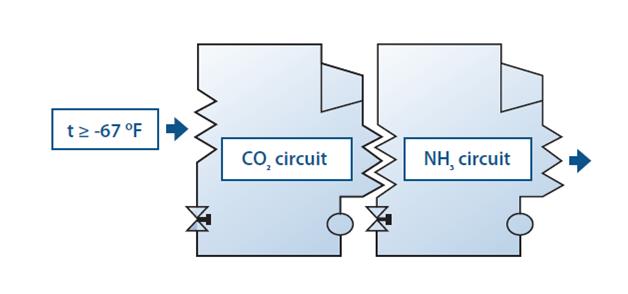

Food processors and distributors are under constant pressure to produce more while spending less on operations. For plant owners looking for greener and more efficient secondary refrigerants, a carbon dioxide (CO2)/ammonia (NH3) cascade system is a viable option. In addition to providing 0 ozone depletion potential (ODP) and 1 global warming potential (GWP), CO2/NH3 cascade systems offer several benefits for food processing and low-temp distribution facilities including:

1. Lower operating costs – refrigeration systems are most efficient at 100% load. But the refrigeration systems in most processing and cold storage facilities don’t run at full load for much of the time. During these times of partial loading, energy efficiency is more difficult to achieve. A CO2/NH3 cascade system uses less energy per ton of refrigeration when compared to other refrigeration systems at full load, but the difference can be even better at part load, especially when operating at evaporating temperatures of -35oF to -60oF.

2. Lower capital costs – using CO2 instead of ammonia for lower temperatures takes advantage of CO2’s unique physical properties, resulting in smaller pipes, smaller pumps, less insulation, and less installation labor when compared to two-stage ammonia systems.

3. Ammonia charge reduction – a CO2/NH3 cascade system allows designers to limit ammonia charge to the machine room. Only CO2 is present in the processing and/or storage areas. For large low-temperature freezing systems, the reduction in ammonia charge can be significant.

Many owners are considering propylene glycol, a secondary refrigerant chilled by ammonia or another refrigerant, as a strategy to reduce ammonia charge for the higher temperature (above freezing) storage and process loads. For these applications, CO2 brine, often already part of the low-temperature cascade system, can be circulated to higher temperature storage loads serve as an efficient and less-expensive alternative to glycol.

4. Reduced compliance costs – in many cases, CO2/NH3 cascade systems can be designed with an ammonia charge below 10,000 pounds, giving owners the opportunity to reduce the costs associated with PSM and RMP compliance.

5. Constant positive pressure – because CO2/NH3 cascade systems always operate at a positive pressure, there is minimal concern about non-condensable build-up, and air and moisture cannot invade the refrigeration piping through vacuum leaks.

6. Quality and throughput improvements – frozen foods processors often seek lower process freezing temperatures to enable faster freezing, which optimizes food quality and enables increased throughput. With CO2/NH3 cascade systems, lower temperatures (and higher production yields) are achievable with less investment and less operating costs than conventional refrigeration systems.

To learn more about implementing a CO2/NH3 cascade system for your facility, contact me at foodforthought@stellar.net.