Did you know CO2 has been used in mechanical systems since the 1800s? However, over time, the industry has gravitated away from CO2 toward lower pressure, synthetic refrigerants like Freon. But now that synthetic refrigerants are being phased out due to their negative environmental impacts, it’s time to take a renewed look at CO2 as a viable refrigerant alternative. CO2 has several key differentiators from other common refrigerants, including:

- High operating pressures

- Narrow range of operating temperatures

- Much higher pressure at the triple point (-69.9 °F at 75.1 psia)

- Much lower temperature at the critical point (87.9 °F )

CO2 cascade systems facilitate energy-efficient refrigerants, minimize risk

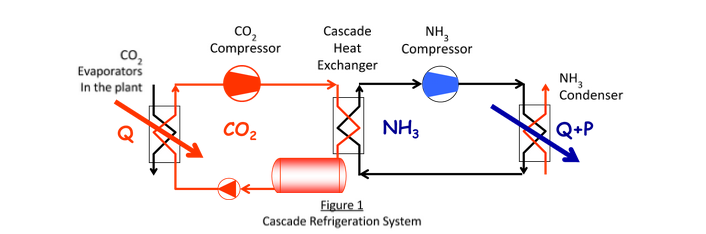

CO2 systems that operate below the critical point are called “subcritical” and are most commonly applied in a cascade configuration (see figure 1 below), or a two-stage refrigeration system. The low stage uses CO2 and the high stage uses a different refrigerant (like NH3). This setup takes advantage of each refrigerant’s properties, only using them in areas where they best apply.

The CO2, used on the low stage, is distributed to the evaporators throughout the facility. Ammonia, used on the high stage, is completely contained in the machine room. This configuration facilitates the use of two of the most energy-efficient refrigerants on the market while minimizing the risk of distributing large charges of ammonia throughout the facility. For industrial applications, this is an excellent solution.

The cost of CO2/NH3 cascade systems vs. ammonia systems

From an initial cost standpoint, CO2/NH3 cascade systems have historically cost 10 to 15 percent more than conventional two-stage ammonia systems. However, as manufacturers have started bringing a complete line of standard products for CO2 to market and as more engineers and contractors become comfortable with providing these systems, the cost is becoming very competitive with a typical ammonia system. And for applications where the evaporator temperatures are below -40 °F, the systems are becoming less expensive.

CO2 efficiency vs. ammonia efficiency

From a pure theoretical standpoint, CO2 is slightly less efficient than ammonia, but this difference decreases as the evaporator temperature drops. But because CO2 is a very dense gas, the size of the equipment needed to provide the same refrigeration effect is significantly smaller.

A compressor running with a -40 °F saturated suction temperature (SST) on CO2 is almost 10 times smaller than the same compressor for ammonia. This facilitates the use of reciprocating compressors which have a better part load efficiency than standard screw compressors—and they’re cheaper.

Since most refrigeration systems operate in some form of part loading over the year, the CO2 system’s efficiencies are very competitive with ammonia systems and in some cases even more efficient, especially at lower temperatures.

Key benefits of using CO2

The real advantage of using CO2 is mitigating risk. For example, a typical 200,000-square-foot refrigerated warehouse using a conventional central station ammonia system will have a refrigerant charge in the neighborhood of 40,000 lbs of ammonia. The same facility using CO2 on the low stage and ammonia on the high stage will have a refrigerant charge of less than 7,000 lbs. This level of charge is below the threshold limit that triggers requirements with OSHA for compliance to Process Safety Management (PSM) and with the Department of Homeland Security for compliance with the Chemical Facility Anti-Terrorism Standards (CFATS) program.

And because ammonia is contained in the machine room, there is limited risk of for leaks that could injure or kill someone.