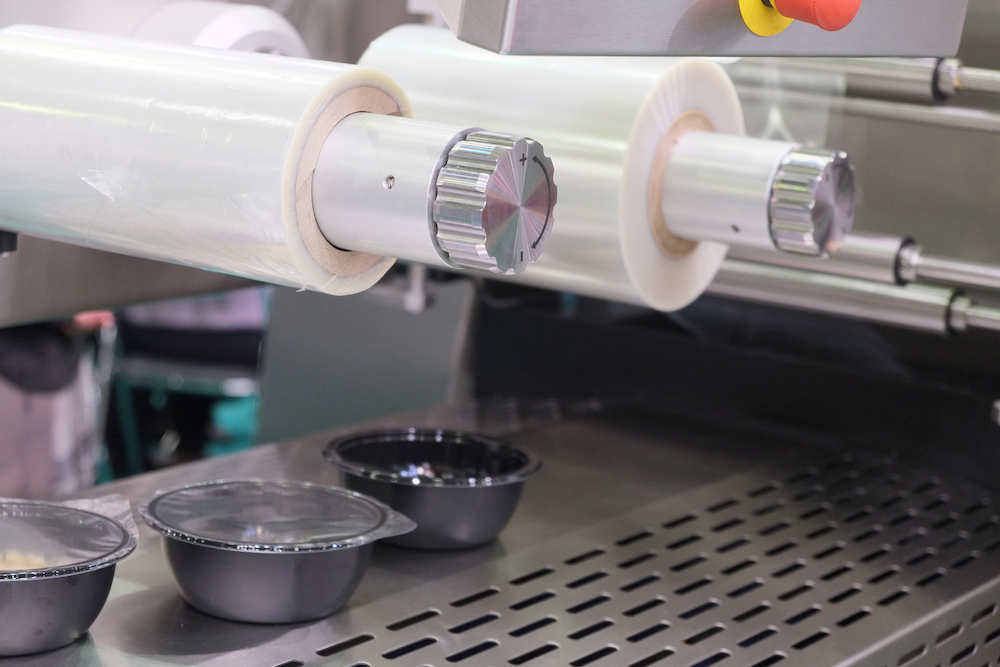

[Timeline] 9 Defining Moments for the Food Processing Industry

July marks an exciting milestone for Stellar: our 30th anniversary. While we’ve celebrated plenty of remarkable moments over the past three decades, we know we’re not the only ones. Food processing has experienced several turning points of its own, signifying key changes that have molded food manufacturing as we know it today. Continue Reading “[Timeline] 9 Defining Moments for the Food Processing Industry”

![[Timeline] 9 Defining Moments for the Food Processing Industry](https://stellarfoodforthought.net/wp-content/uploads/2015/07/Defining-Moments-for-the-Food-Processing-31.png)