Proper air balance in a food plant is required to maintain the environmental parameters that keep the space food-safe, including temperature, humidity and the frequency of air replacement. Additionally, the direction of airflow is important, especially when dealing with raw animal products.

Now, in the post-pandemic world, clean, fresh air is more valuable than ever. As the world gets back to work, it’s important to examine your facility’s air system to ensure it’s up to par to keep workers and consumers safe.

Maintaining proper air balance and quality ensures:

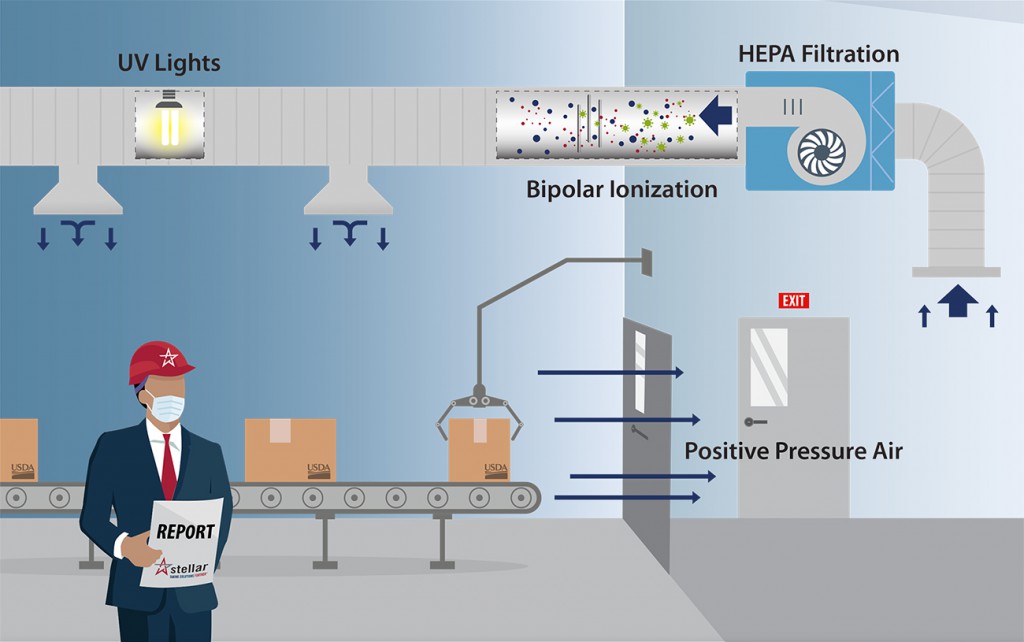

1. A safer work environment — Keeping air moving at a faster pace in areas where workers are present can help reduce the risk of person-to-person COVID-19 transmission through aerial droplets, which is believed to be the main mechanism through which the virus has spread. This can be accomplished by creating a positive pressure environment, where the air pressure is higher inside an area than surrounding rooms. The higher relative pressure forces the air to constantly vent outside the working area as it’s refreshed with clean air.

2. Elimination of airborne contaminants — HEPA filtration can remove airborne particles like dust, dirt and flying insects from being introduced to your plant through the ventilation system. On top of that, the entire spectrum of ultraviolet (UV) light has been shown to kill bacteria and viruses, with UV-C light being the most effective. However, UV-C light sources must be concealed because direct exposure to people can be harmful.

Additionally, in meat-processing facilities, dangerous food-borne pathogens like salmonella and listeria must be mitigated for consumer and worker safety. The direction and frequency of air flow in these facilities is paramount to removing these dangerous pathogens. Air from areas where raw meat and poultry are handled should never flow to areas where the finished product could be exposed to airborne contaminants.

3. Condensation control — Excess moisture and condensation can undermine the extensive measures required to create a tightly controlled food safe processing space. If moisture is able to condense in cracks and corners, and on hard-to-reach surfaces on machinery, it can lead to bacterial and microbial growth, which can contaminate products.

4. Temperature control — In order to maintain sanitation and safety standards, room temperatures in food plants must be precisely controlled. That means adjacent rooms with temperature differences shouldn’t flow into each other, where they can cause fluctuations.

If you’d like to learn more about updating your HVAC system’s filtration and air balance, please email me at foodforthought@stellar.net

please send me a brochure on your tools in a pork plant