Numerous substances used in industrial refrigeration are believed to be responsible for ozone depletion, especially a common low-temperature refrigerant – R-22. While R-22 is widely used in numerous food plants and cold storage facilities, an international treaty, the Montreal Protocol on Substances that Deplete the Ozone Layer, calls for a halt in the production of R-22 and other chemicals damaging to the atmosphere.

This significant change in how food manufacturers and distributors conduct their day-to-day operations is leaving many questions unanswered. For those bracing themselves and wondering what’s next, here’s what you need to know:

What’s the timeline and how long will I be able to purchase R-22?

The Montreal Protocol calls for a gradual phase-out of R-22, with complete elimination by 2030. Production of new R-22 equipment ceased in 2010, and with a lifespan of approximately 15 years, most of these units are one third of their way through their useful live. The phase out of the manufacturer of R-22 refrigerant has already begun. The EPA plans to end all production and import of R-22 by 2020. Recycled R-22 will be available for use in R-22 units, but as the available supply of R-22 decreases, costs will inevitably rise.

Can I upgrade or retrofit my existing R-22 system?

Food processing plants should be planning for new refrigeration systems rather than investing in existing R-22 units. As these pre-2010 units continue to age and R-22 refrigerant becomes scarcer, costs to maintain these systems will increase, both for maintenance and for the refrigerant. While switching out the refrigerant of an R-22 unit to an alternative blend is an option, it’s not necessarily feasible for all plants. Changing out the refrigerant requires shutting down the system, changing out seals and other components and flushing it numerous times, which can require significant downtime. This may be a short-term option for smaller systems, but for bigger systems it becomes too costly and time consuming.

What do I need to know about investing in a new refrigeration system?

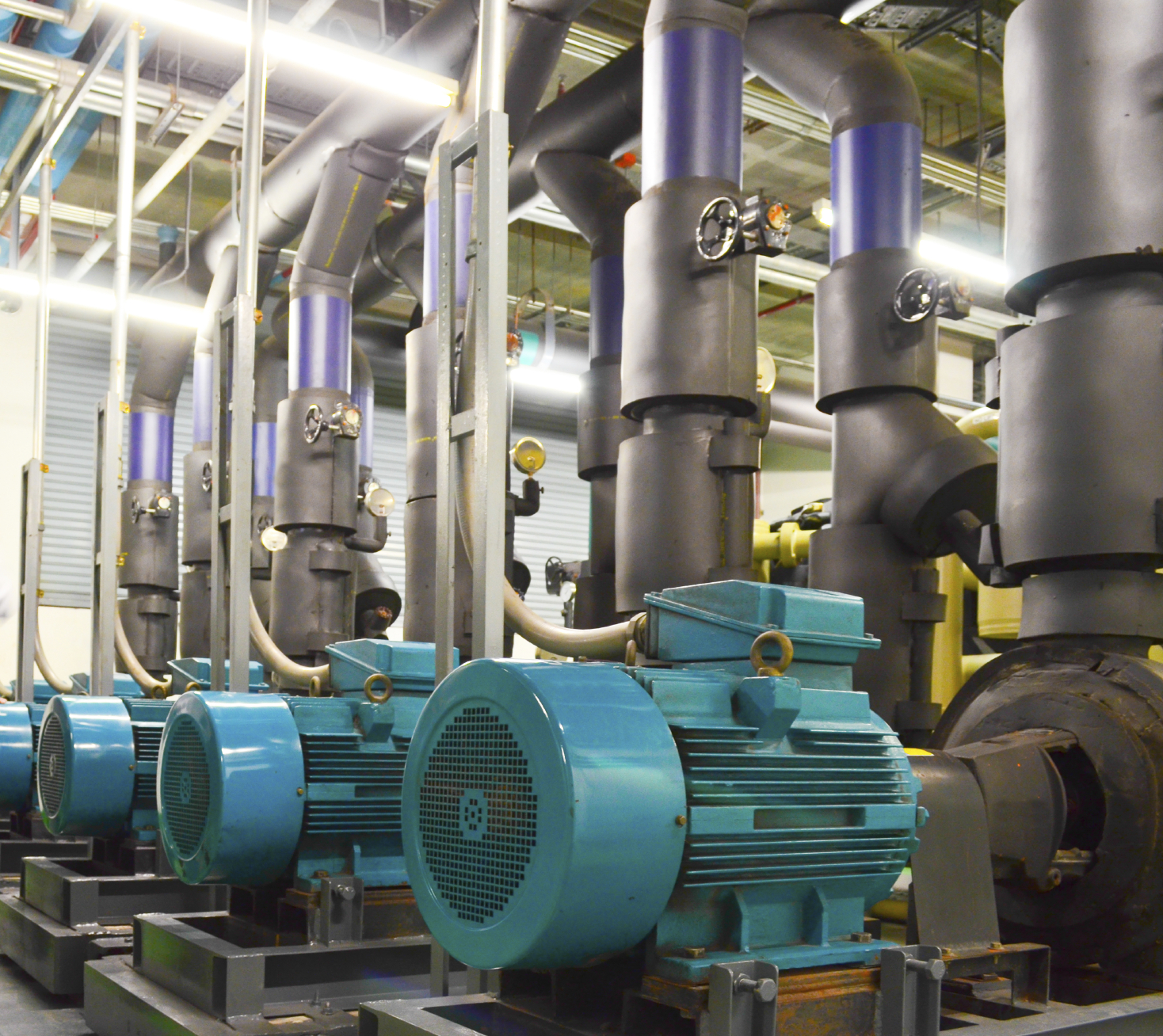

The decision for an industrial processing plant to invest in a refrigeration system requires a detailed, thoughtful plan. The costs for the actual system will vary depending on your facility’s process requirements, yet it is equally important to develop a phased approach that incorporates a plan for downtime during the transition.

What are the alternatives to R22?

There are a number of environmentally friendly refrigerants available. Ammonia and CO2 are natural refrigerants which have zero ozone depletion and zero global warming potential (GWP). Ammonia continues to be a popular alternative, followed by CO2 and blends, which include R404A, R407C, R410a, and R507, among others. The alternative blends have a relatively high GWP, which potentially puts them at risk for phase out at some future date.

Is there a difference in efficiency of new refrigerants?

These new units are often more compact, with fewer and smaller pipes, thus requiring a reduced volume of gas. Their increased efficiency can result in less energy consumption and lower energy costs.

To learn more about options for phasing out R22 refrigerants, email me at foodforthought@stellar.net.