5 Common Oversights in Industrial Refrigeration Compressor Maintenance (and How to Combat Them)

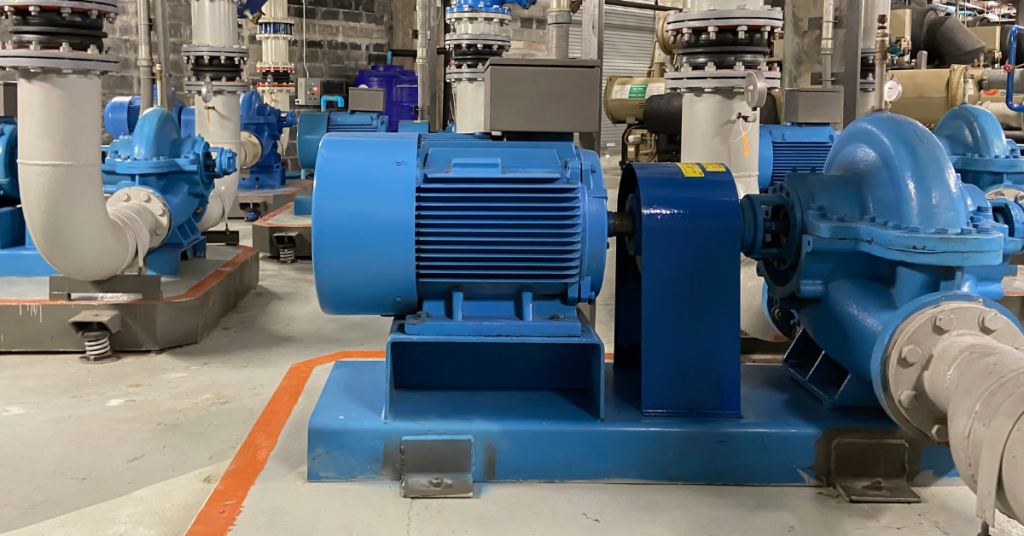

Compressors play a vital role in industrial refrigeration systems, serving as indispensable components. As time passes, both compressors and their bearings undergo degradation, posing a potential threat of facility downtime and consequent negative impact on your financial performance. To guarantee the consistent and efficient operation of this equipment, the implementation of a rigorous maintenance program becomes imperative.

Staying on top (or even ahead) of maintenance will prolong the compressor’s life and avoid a shutdown. In fact, 82% of manufacturing companies have experienced unplanned downtime, costing as much as $260,000 an hour, according to one study.

Continue Reading “5 Common Oversights in Industrial Refrigeration Compressor Maintenance (and How to Combat Them)”

![Does your PSM compliance training meet the latest OSHA requirements? [infographic]](https://stellarfoodforthought.net/wp-content/uploads/2022/01/PSM-Training.png)

![How Stellar Services Industrial Refrigeration Compressors [VIDEO]](https://stellarfoodforthought.net/wp-content/uploads/2019/12/How-We-Service-Industrial-Refrigeration-Compressors-VIDEO.png)

![Installing Packaged Refrigeration vs. Traditional Systems [Infographic]](https://stellarfoodforthought.net/wp-content/uploads/2018/08/083018_Feature-image.png)