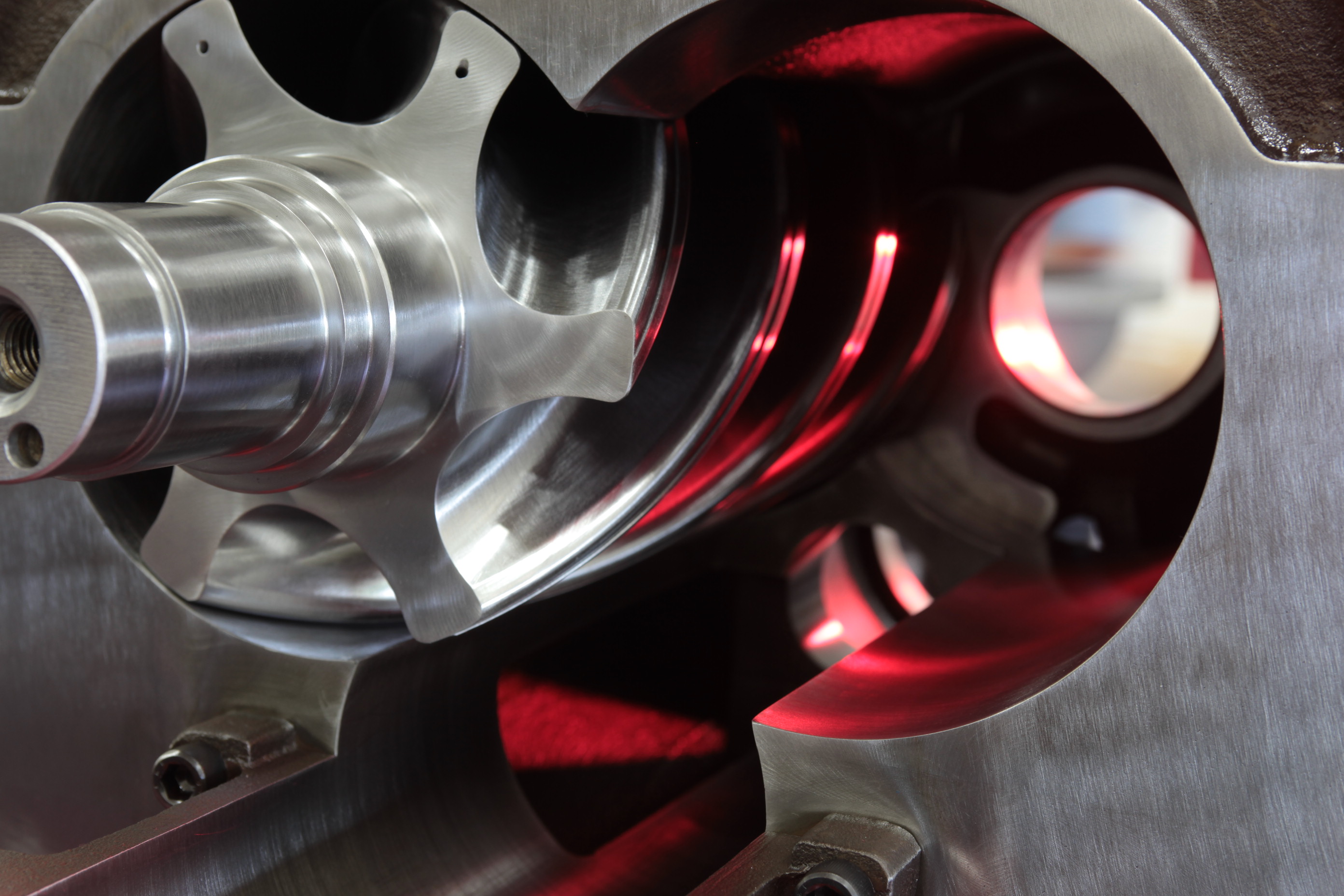

The One Mistake You’re Making With Your Compressor Logs

After working with compressors for nearly three decades, there’s one mistake I see people making time and time again when it comes to their compressor maintenance. They keep their daily logs, recording necessary temperatures regularly, but when they’re through, they simply put the logs aside and don’t look at them again. The results are not analyzed for corrective measures, if discovered. Are you looking back to ensure you’re addressing the inconsistencies and issues you notice during your compressor evaluations? Analyzing the daily logs is just as important as writing it down. Continue Reading “The One Mistake You’re Making With Your Compressor Logs”