Food plant owners who work with frozen products must have a thorough understanding of the freezing process and what it does to food. Freezing, done well, preserves nutrients and provides a good-as-fresh product for the customer. Done badly — well, we’ve all pulled a forgotten, frost-encrusted steak out of the bottom of the freezer before. It’s not very appetizing. This two-part blog series will take a look at best practices for freezing and the applications of various types of freezers.

The basics of freezing foods

While freezing may seem like a straightforward process, it takes a precise understanding of several key factors to ensure it’s done right. Proper freezing preserves the food’s freshness and taste, and at the same time ensures it is stored safely. Freezing speed, temperature requirements and the type of food being frozen all play a role in achieving both quality and safety. Consider the following guidelines for freezing food products:

- Freeze foods as quickly as possible—The food product isn’t actually what freezes, but rather the water inside its cells. When frozen slowly, the water is allowed to expand into large, disruptive ice crystals, which rupture the cell walls. However, quickly freezing food reduces the size of the ice crystals, so the cells remain intact.

- Fewer ruptured cells equals better quality and texture.

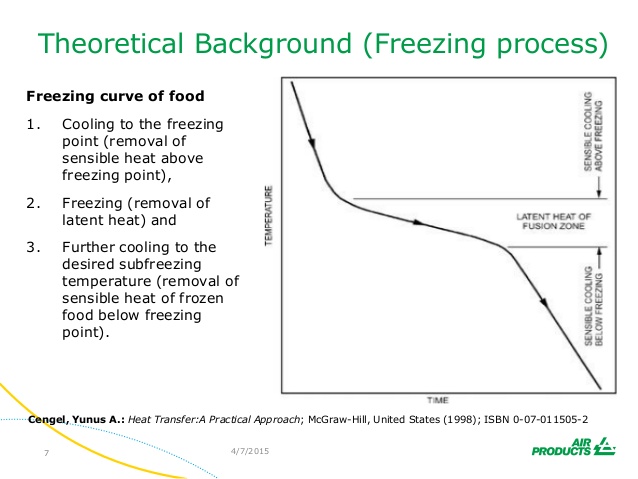

But, freezing takes time—Paradoxically, while it’s best to freeze food quickly, it’s also important to allow an adequate amount of time for the food to fully freeze. Different foods require different freezing temperatures, but they all adhere to a basic freeze curve. Temperature decreases steadily until the freezing point is reached. Once there, the temperature remains constant for a long time as water changes to ice, which requires added energy.

But, freezing takes time—Paradoxically, while it’s best to freeze food quickly, it’s also important to allow an adequate amount of time for the food to fully freeze. Different foods require different freezing temperatures, but they all adhere to a basic freeze curve. Temperature decreases steadily until the freezing point is reached. Once there, the temperature remains constant for a long time as water changes to ice, which requires added energy.

- This is because the hidden heat, called latent heat, must be removed before every water molecule can change state.

- Freeze food at peak quality—Freezing a food at its freshest creates the best end-product. At 0℉, enzymes are inactivated, which slows deterioration or ripening processes. Thus, to keep a food product as fresh as possible, you must freeze it before its enzymes have had a chance to deteriorate the food much, if at all. Time between harvest and freezing varies according to the type of food:

- For animal products, freezing should occur as soon as possible after the raw meat product is created.

- Fruits should be frozen as soon as possible after harvest.

- Most vegetables require partial cooking, called blanching, to prevent deterioration. Blanching involves partially cooking the vegetable in boiling water or a microwave oven, then rapidly cooling it prior to freezing.

- Storage and shipping require lower temperatures—Foods generally freeze at temperatures just a few degrees below water’s freezing point: 32°F. However, for both storage and shipping purposes, frozen food must be kept at much lower temperatures. Studies have shown that bacteria can live on food even at freezing temperatures. In general, safe shipping of products like frozen meals and vegetables can occur at temperatures below +10°F, though most companies mandate 0℉.

- Ice cream is a special case. It requires a maximum storage temperature of -20°F, and a shipping temperature never greater than -10°F. At warmer temperatures, the tiny ice crystals that give ice cream its creamy texture begin to grow, which creates a grainy texture.

While moving product is a top priority for food processors, it’s important to understand how freezing works and what happens to food when it’s frozen. Creating frozen food products that are both safe and enjoyable to eat requires a little vigilance. Manufacturers must be sure to pay attention to such factors as freezing speed and the proper storage temperatures of frozen products throughout the distribution chain.

If you’d like to learn more about the elements of process freezing, email me at foodforthought@stellar.net.