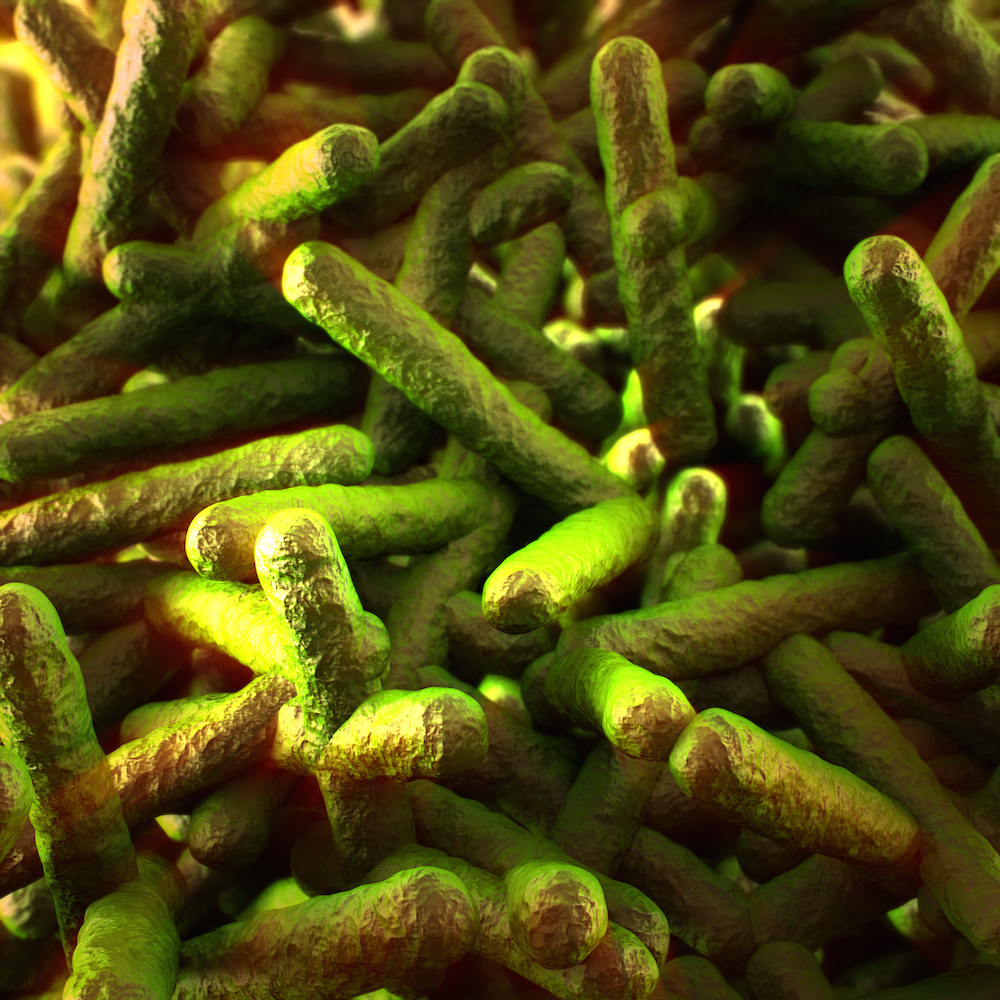

Listeria is a foodborne illness that can have dire consequences–sometimes, deadly. The bacteria is characteristically persistent, able to not only thrive for years, but within frozen storage and outside of the expected environments, such as meat processing plants. Are you sure you’re taking the proper measures to ensure listeria isn’t growing in your facility?

Important listeria characteristics to remember

According to the FDA, listeria exhibits characteristics including:

- Survives and grows at refrigeration temperatures

- Tolerates high salt concentrations (non-chlorinated brine chiller solutions)

- Withstands frozen storage for extended periods

- Is more heat resistant than other food-borne pathogens

- Multiplies between 86 and 98.6 degrees Fahrenheit

How to prevent listeria within your food manufacturing facility

You can control listeria with the combination of a few key factors:

- Traffic control

- Sanitary building design

- Sanitary process equipment design

- Effective sanitizing procedures

Here’s how you can pay careful attention to these commonly documented sources of listeria within food processing plants, from the most common to least common:

- Floors—Provide level surfaces with proper slopes to eliminate the ponding of water.

- Flood drains—Ensure the actual floor drain body isn’t located directly under process equipment. Drains should be made of cleanable materials and should be spaced to serve no more than 600 square feet.

- Cleaning aides (brooms, hoses, carts)—Segregate tools for raw and ready to eat (RTE) foods by color. One possible solution is to purchase red tools for raw and blue for RTE; that way users visually recognize if the tools are within their proper zone.

- Food contact surfaces–Ensure that equipment adheres to the American Meat Institute Foundation’s new Sanitary Design Principles, recently revised to specifically reduce listeria in RTE meat and poultry products. These include:

- Cleanable to a microbiological level

- Made of compatible materials

- Accessible for inspection, maintenance, cleaning and sanitation

- No product or liquid collection

- Hermetically sealed hollow area

- No niches

- Sanitary operational performance

- Hygienic design of maintenance enclosures

- Hygienic compatibility with other plant systems

- Validated cleaning and sanitizing protocols

- Condensation—Minimize moisture in critical work areas by means of temperature and humidity control via mechanical systems, ventilation and refrigeration.

- Walls—Provide cleanable surfaces such as precast concrete, insulated metal panels (IMP) and other sealed surfaces that are smooth and consistent.

- Compressed air—Use air dryers to lower the dewpoint of compressed air. If piping and devices are located above process equipment where steam rises, the cold air piping and the hot air from the steam will cause condensation.

If you’d like to learn more about food safety, feel free to email me at foodforthought@stellar.net or connect with me on LinkedIn.

One place that we have found over the years in food plants is floor coatings, if you see a crack or void in your floor coating you can bet there is bacteria growing under the coating the only way to fix the issue is remove it until you find well bonded areas.