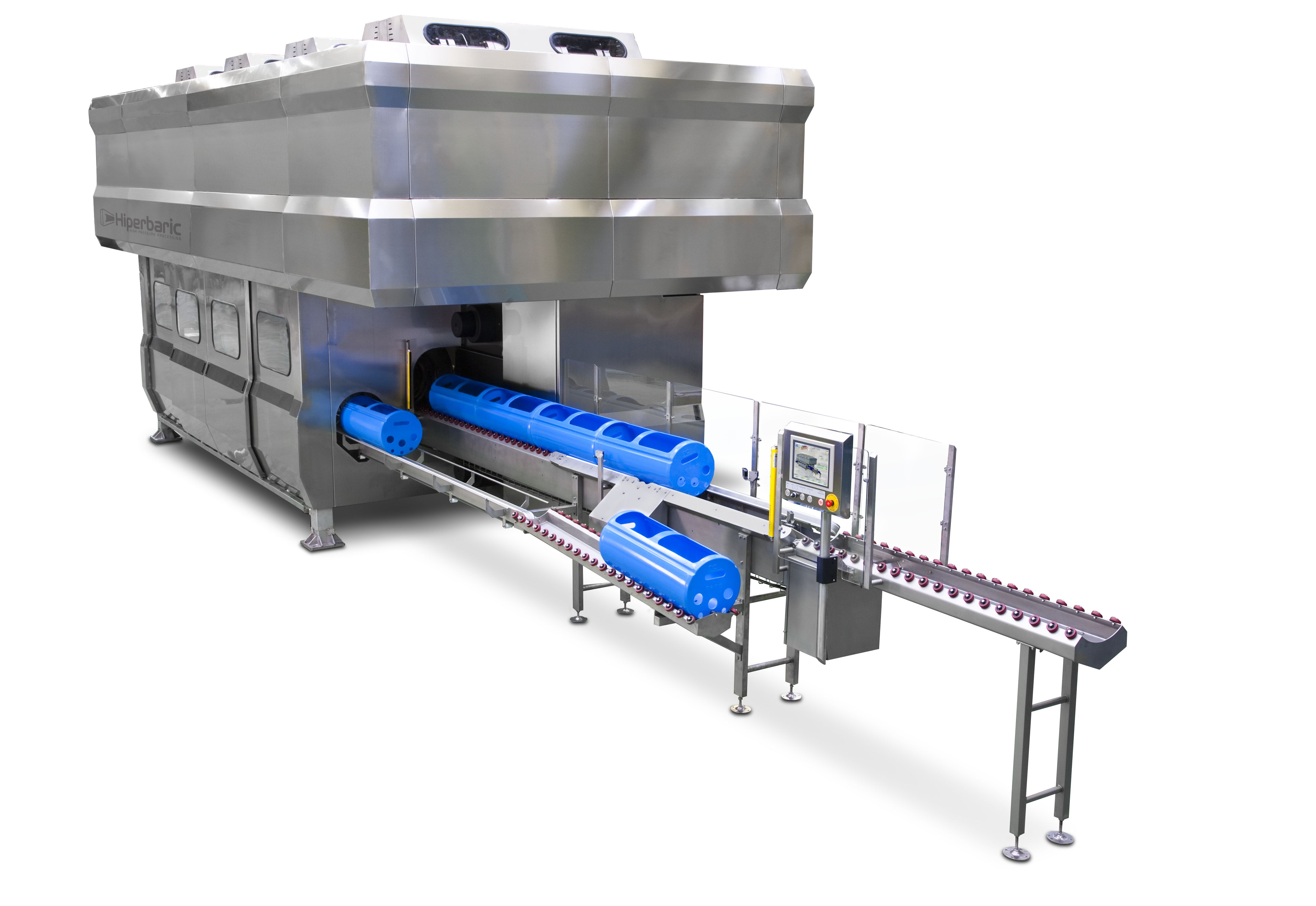

High pressure processing (HPP) is gaining popularity among food manufacturers as a method that induces a pasteurizing effect on packaged food without subjecting the products to thermal energy. The recent explosion of the health and organic markets is partially responsible for the increased acceptance of this natural and environmentally friendly process.

As its name suggests, HPP uses pressure, rather than thermal or chemical treatments, to extend the product’s shelf life and product integrity by terminally disrupting the life cycle of food spoiling bacteria, food-borne pathogens and other microbiological threats. While traditional and thermal methods of food preservation can alter a food’s flavor and nutritional value, HPP preserves the food’s original sensory characteristics including taste and smell.

HPP works by exposing products to a high level of hydrostatic pressure, typically up to 87,000 pounds per square inch. Pressure is applied uniformly, typically for three to five minutes, to allow the product package to maintain its shape as long as the product is suitable to withstand the pressure. The product must contain water and harbor no internal cavities that may collapse under pressure. This pressure disrupts and kills dangerous bacteria including salmonella, E. coli and listeria, thus extending the product’s shelf life. Foods that would typically have a three-to-four-day shelf life through traditional pasteurization are fresh up to 30 days with HPP.

The key advantages of HPP are:

- Food quality – foods retain their original taste, smell, consistency and quality

- No nutritional impact – HPP does not affect foods at their molecular level allowing them to retain their nutritional value, including proteins, enzymes, nutrients, prebiotics, vitamins and minerals

- Food safety – the process destroys dangerous pathogens to meet food safety requirements

- Longer-lasting products – HPP extends product shelf life up to 30 days or longer by inactivating dangerous bacteria

- Fewer food preservatives– the need for preservatives is greatly diminished or removed, especially in packaging

- A greener process – this environmentally friendly and sustainable process requires only water and electricity.

- Higher production yields: Facilitates the meat extraction of mollusks (clams and oysters) and crustaceans (lobsters and crabs).

Products that best lend themselves to HPP include items packaged in flexible containers, including packaged meats, juices and seafood, in addition to sauces and dressings sold in pouches.

If you’d like to learn more about HPP and its benefits, email me at foodforthought@stellar.net.