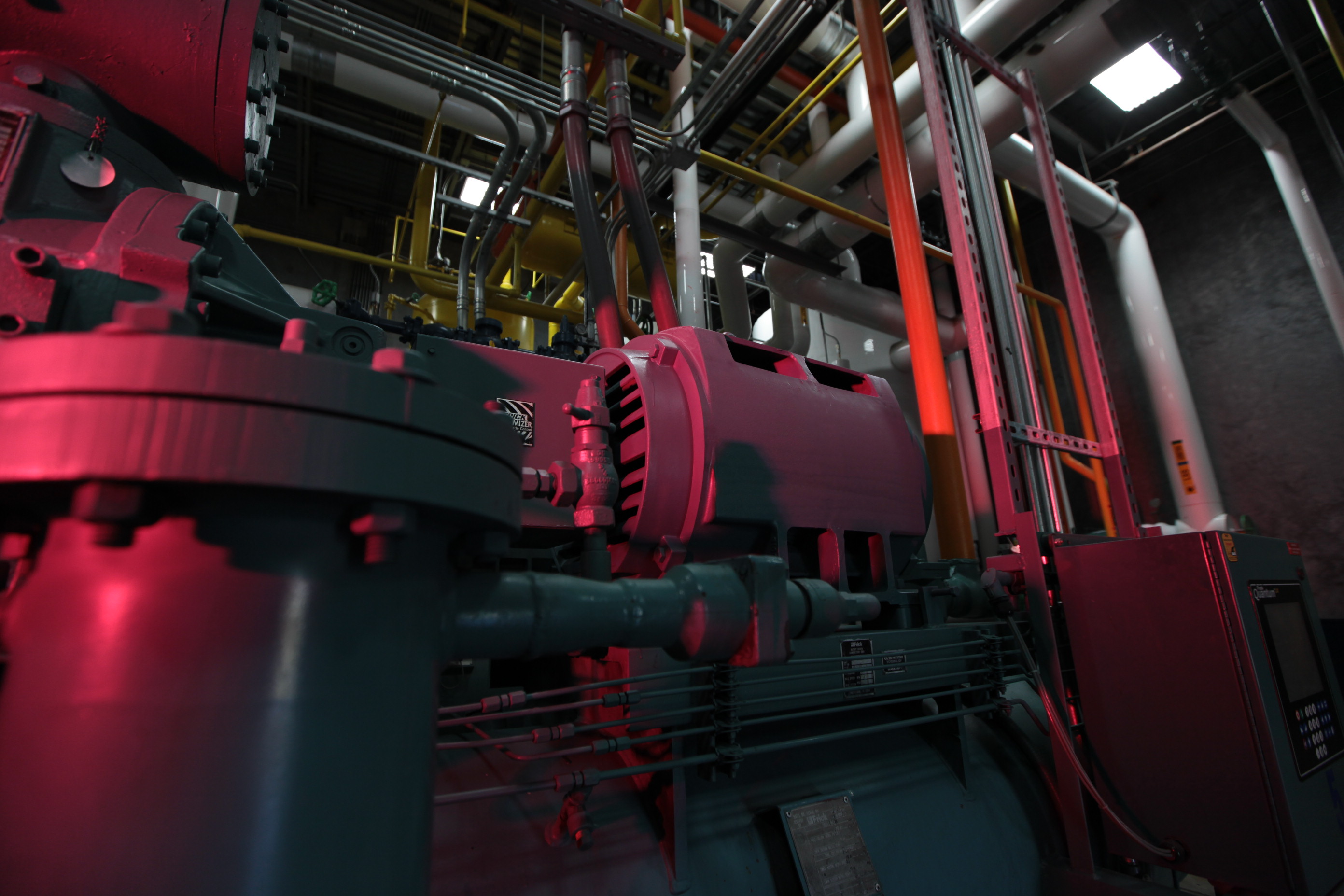

Can Compressed Air Systems be a Source of Contamination?

Did you know that compressed air systems can be a source of contamination in your food plant? Dangerous bacteria and pathogens can be difficult to spot in your facility—especially if they are airborne. It’s a common misperception that compressed air is considered as clean as the air from the outdoor environment that surrounds your facility—NOT true. Once in the compressor, the air outside of your facility (ambient air) mixes with other elements within your compressor (i.e., corrosion, worn seals). Whatever is not caught in your filtration system is then circulated throughout your plant.

Continue Reading “Can Compressed Air Systems be a Source of Contamination?”

![[Infographic] Refrigeration Compressor Red Flags](https://stellarfoodforthought.net/wp-content/uploads/2023/06/REP-stellar-infographic.jpg)