Billions of particles can lace unconditioned air with dust, dirt, bacteria and viruses. That’s why your food plant’s air filters are crucial to preventing contamination and ensuring food safety. But when it comes to filtration, more isn’t necessarily better, especially when it comes to high-efficiency particulate air (HEPA) filters. HEPA filters are a necessity for many plant environments, but the level of filtration can vary, potentially making certain options expensive overkill for others.

MERV ratings and HEPA filters

According to the U.S. Environmental Protection Agency (EPA), HEPA filters “theoretically remove at least 99.97% of dust, pollen, mold, bacteria and any airborne particles with a size of 0.3 microns (µm).” This means that these filters can remove all yeast, mold, bacteria and other particles that are larger than 0.3 µm. The U.S. Food and Drug Administration (FDA) recommends using HEPA filters in areas where ready-to-eat foods are processed or exposed.

However, unless your plant requires a sterile environment (e.g., aseptic packaging), most spaces require only 95% filtration which can be achieved through a less costly filter like a MERV 15.

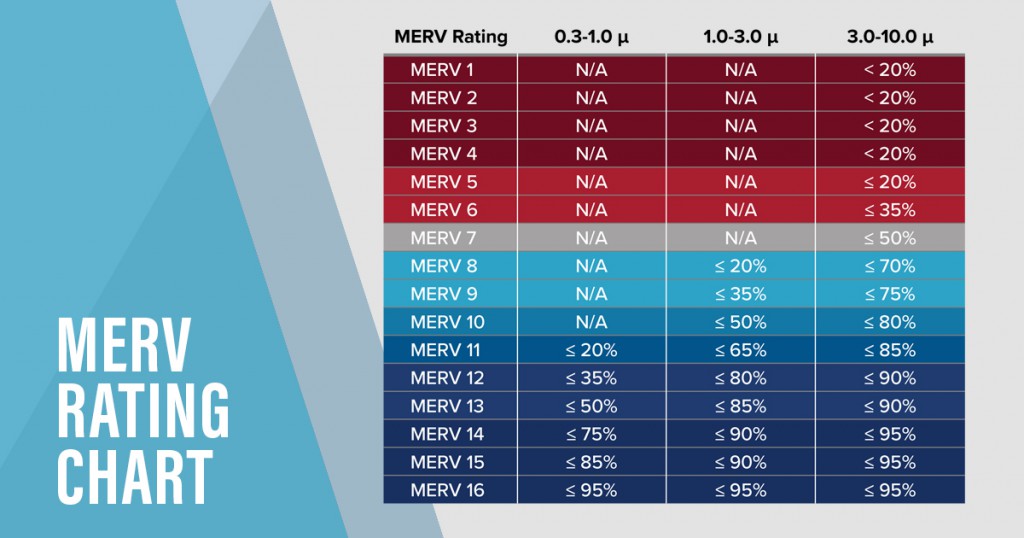

Air filters are rated on the MERV (Minimum Efficiency Reporting Value) scale, which officially tops out at MERV 16. HEPA filters surpass MERV 16 and are at least 99.97% efficient at filtering 0.3 μm mass median diameter (MMD) particles in standard tests.The table below, based on the ASHRAE Standard 52.2-2017 MERV table, extends the traditional ratings to include HEPA filtration efficiencies.

In light of the global pandemic, HEPA filters have garnered more attention since they can capture the coronavirus that causes COVID-19. There are also other methods to help purify the air in a facility, such as bipolar ionization and UV-C lighting that can kill viruses and bacteria, which may be used to supplement filtration.

That said, the highest-rated MERV filtration may not be necessary; and depending on your facility, product and personnel, a filter with a lower rating may be sufficient.

Here are some reasons why HEPA filters may not be needed for your plant:

- Types of organisms — At a 99.99% efficiency, HEPA filters do offer finer filtration, catching more particles than filters that can only catch 95% of organisms. However, these organisms are not typically free-floating. This means that they are attached to other, bigger particles that are, indeed, captured by the 95% filters. A meat processing plant is an example of a facility with these types of organisms and would thus not require HEPA filters.

- Power — Because HEPA filters cause a higher pressure drop as air passes through, they require about 15% more horsepower to operate, so more energy is used. Also keep in mind that the air handling unit itself may need to be bigger to house HEPA filters because of their larger size.

- Cost of purchase and maintenance — HEPA filters are not only more expensive upfront, they also incur ongoing maintenance costs. These filters need to be replaced once or twice a year depending on the environment of the plant. This can be twice as much as the recommended change intervals for MERV 15 filters, which should typically be changed every 9 to 12 months.

While providing your plant with additional filtration isn’t harmful, HEPA filters may not be your most cost-effective option. Unless your facility is sterile, HEPA filters may result in unnecessary expenses for your plant due to the fact that you could have achieved a satisfactory result with a less costly filter that operates at 95% efficiency, such as a MERV 16.

Air filter maintenance (and the costs of ignoring it)

Regardless of what kind of filter a system uses, it’s imperative to regularly change them. Whether on a schedule or via predictive maintenance technology, routinely replacing air filters ultimately yields cost savings in a number of ways:

- Food safety — A dirty filter can collect dust, dirt and bacteria buildup that could fall from ducts and contaminate products. Not only could this result in wasted batches, but if undetected, could even lead to a costly recall.

- Energy efficiency — When a filter is overdue for replacement, the concentration of captured particles can begin to negatively affect airflow. Air handlers have to work harder to pull air through clogged filters, which could end up costing you more in energy use.

- Life of system — The longer an obstructed air filter causes overexertion of your air handlers and system, the more maintenance it may need in the future. Over an extended period of time, this can shorten the lifespan of equipment.

With today’s predictive analytics tools, replacing air filters can be as easy as an internet-connected sensor notifying you when attention is required — and before a problem turns worse. For example, a significant decrease in air pressure within an HVAC system or ductwork often signals a blockage or filter problem. A dedicated sensor can detect such pressure changes, making routine air filter changes easier to track. A monitoring system would then alert technicians to address the filter problem immediately to avoid unscheduled downtime and unwanted quality issues.

These sensors can often be incorporated into the design specifications for minimal cost and allow the operator to check the pressure and age of the filter via the control system interface. Stellar’s refrigeration experts can help identify your air filtration requirements and determine the best filters to suit your facility’s needs.

Have a question or want to learn more about HEPA filtration? Leave a comment below or email me at rhepp@stellar.net.