The Food Facility Safety Double Standard: Keeping Your Maintenance Crew as Safe as Your Product

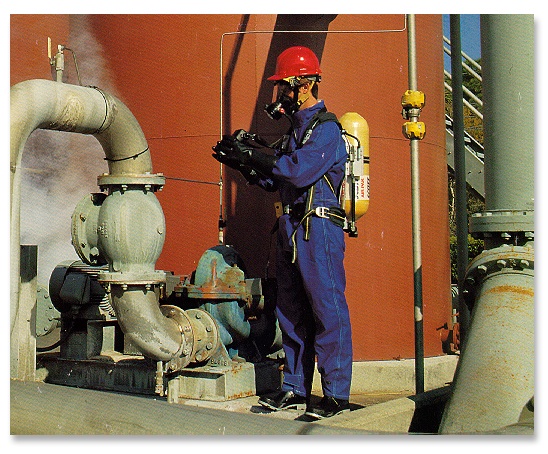

There’s a prevalent double standard when it comes to food facility safety management. Think about the measures taken when a visitor enters a food plant production area: You have to dress out, walk through a foot bath, take off jewelry, wear a smock. All of these precautions are designed to keep your product safe — but what about your maintenance crew?

It’s not uncommon to see safety standards and attention to cleanliness become more relaxed in maintenance areas or on the roof of a food plant. Food safety precautions get a lot of attention because owners (rightfully) fear product contamination and highly publicized recalls, but what about the risks outside your building? One maintenance or construction accident can do just as much damage in negative publicity and lawsuits as a product recall.

![[Timeline] 9 Defining Moments for the Food Processing Industry](https://stellarfoodforthought.net/wp-content/uploads/2015/07/Defining-Moments-for-the-Food-Processing-31.png)