Is Your Refrigeration Automation Up to Par for 2023?

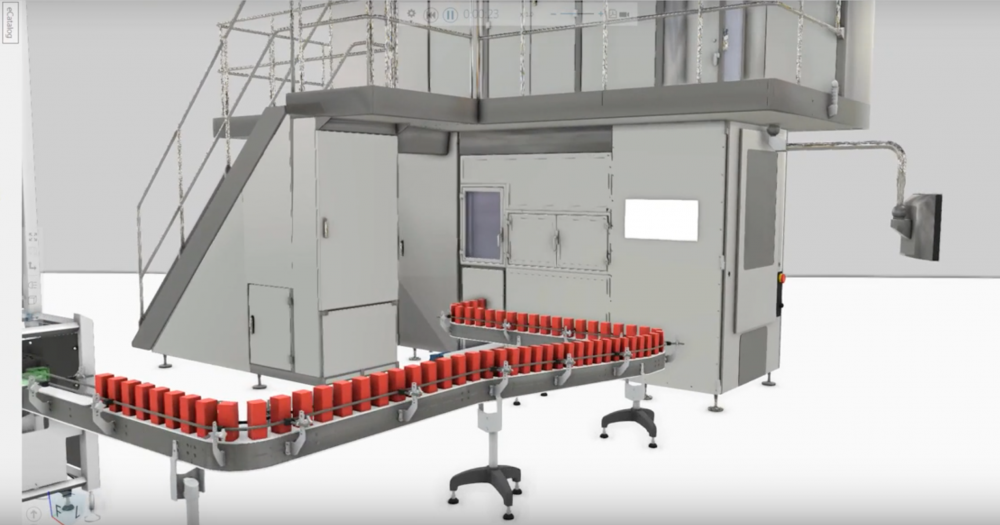

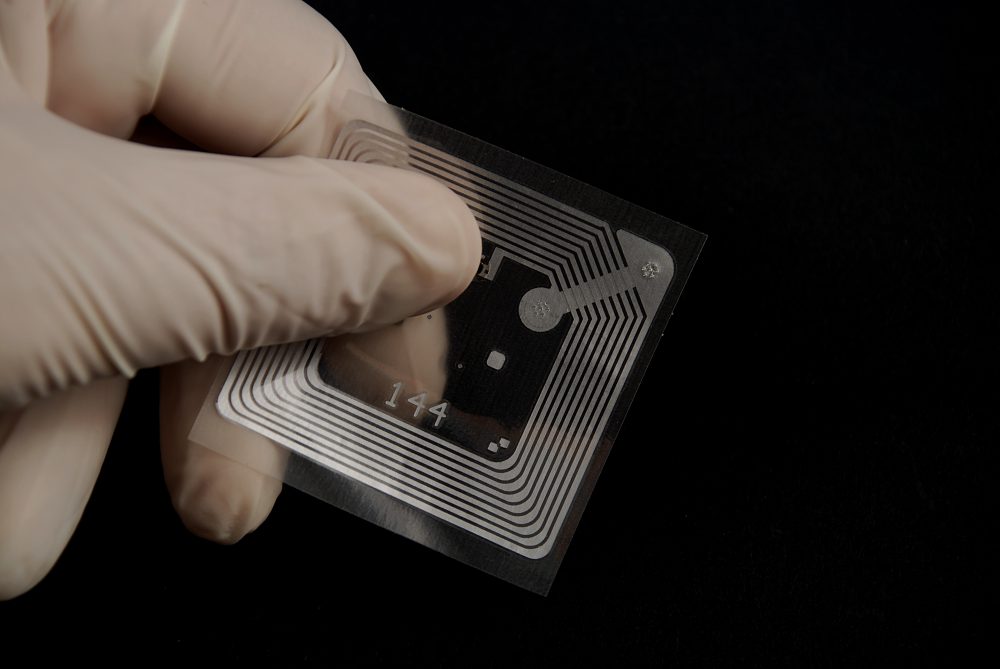

The development of advanced automation controls and technology for industrial refrigeration systems have made critical upgrades possible for owners who want to improve the efficiency, performance, safety and reliability of their systems and overall operations.

However, a refrigeration system running on outdated controls and hardware is like a ticking time bomb and can get quite expensive to repair — not to mention the cost of downtime.

Continue Reading “Is Your Refrigeration Automation Up to Par for 2023?”