Summer is around the corner, which means now is the time to ensure your refrigeration system is ready for the upcoming hot months. Summertime is when these systems work their hardest, so how can you make sure yours is running efficiently and at peak performance levels?

Here’s a short checklist to prepare your refrigeration system for the summer:

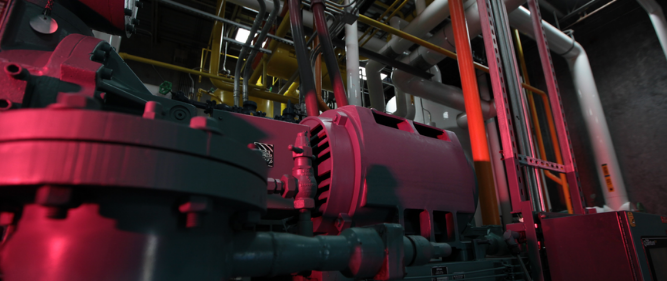

Compressors

- Verify that temperature and pressure sensors are accurate

- Verify load/unload operation for the capacity control

- Cycle compressors to be sure sequencing is set for summer loads

Throughout the year, these configurations may have been tweaked to meet the plant’s needs. Sensors may have lowered or raised, or they simply may need to be recalibrated. Since refrigeration systems run more during summer months, it’s critical to ensure sensors are accurate and that sequencing is set for the hotter months. If not, your compressors could be running too much or not enough, leading to inaccurate and potentially unsafe temperatures.

Condensers

- Clean water sumps

- Clean spray nozzles

- Replace belts, if needed

- Check bearings and fan blades (and lubricate, if necessary)

You likely already address these regular maintenance items throughout the year, but it’s critical to clean your condensers even more in the summer. A dirty condenser could lead to substantially higher costs just to maintain proper temperatures in your building.

Assess the condition of your condenser belts before summer is in full swing. These belts may be running 70% of the time during the rest of the year, but they could be operating up to 100% of the time in summer. Double-check your belts, and if they look like they need replacing soon, you’re better off doing that now.

Evaporators

- Clean coils and drains

- Replace filters routinely

- Check fan operation (and replace belts, if necessary)

- Verify defrost sequencing

Your defrost sequencing is often a “set and forget” aspect of your refrigeration system. However, it’s possible it may have been altered, especially if you have several operators in your plant. If your sequencing is off, you may have rooms being unnecessarily defrosted or not defrosted enough, which leads to added energy costs. Run through your defrost sequencing before the heat of summer to ensure it’s configured properly and running accurately.

Purger

- Check purger operation

- Check system for non-condensables

Purgers eliminate non-condensables from your refrigeration system. If your purger isn’t working as it should during the summer, it could cost you more every month on your energy bill. You may not notice an issue with your purger at other times throughout the year when temperatures and pressures are lower, but if you haven’t checked its condition recently, your first 90-degree day is when your problems will surface.

Other items

- Verify room temperature sensors for accuracy

- Check cold room doors for proper operation and sealing

In today’s world of Industry 4.0, most sensors are connected to automation systems and the internet. But when was the last time you double-checked the accuracy of those sensors against the actual room temperature? If a room temperature sensor is just a few degrees off, it could add to your power bill and increase maintenance on your condensers and compressors that are running more than necessary.

Another common problem: doors that don’t close properly or that have missing or damaged seals. Of course, this is a constant maintenance item, but it must especially be addressed heading into the summer. Abnormal ice buildup inside a temperature-controlled room is a tell-tale sign of a leak.

Do you have specific questions about preparing your refrigeration system for the summer heat? Leave a comment below or email me at foodforthought@stellar.net