How to Evaluate Market Trends to Grow Your Food Business

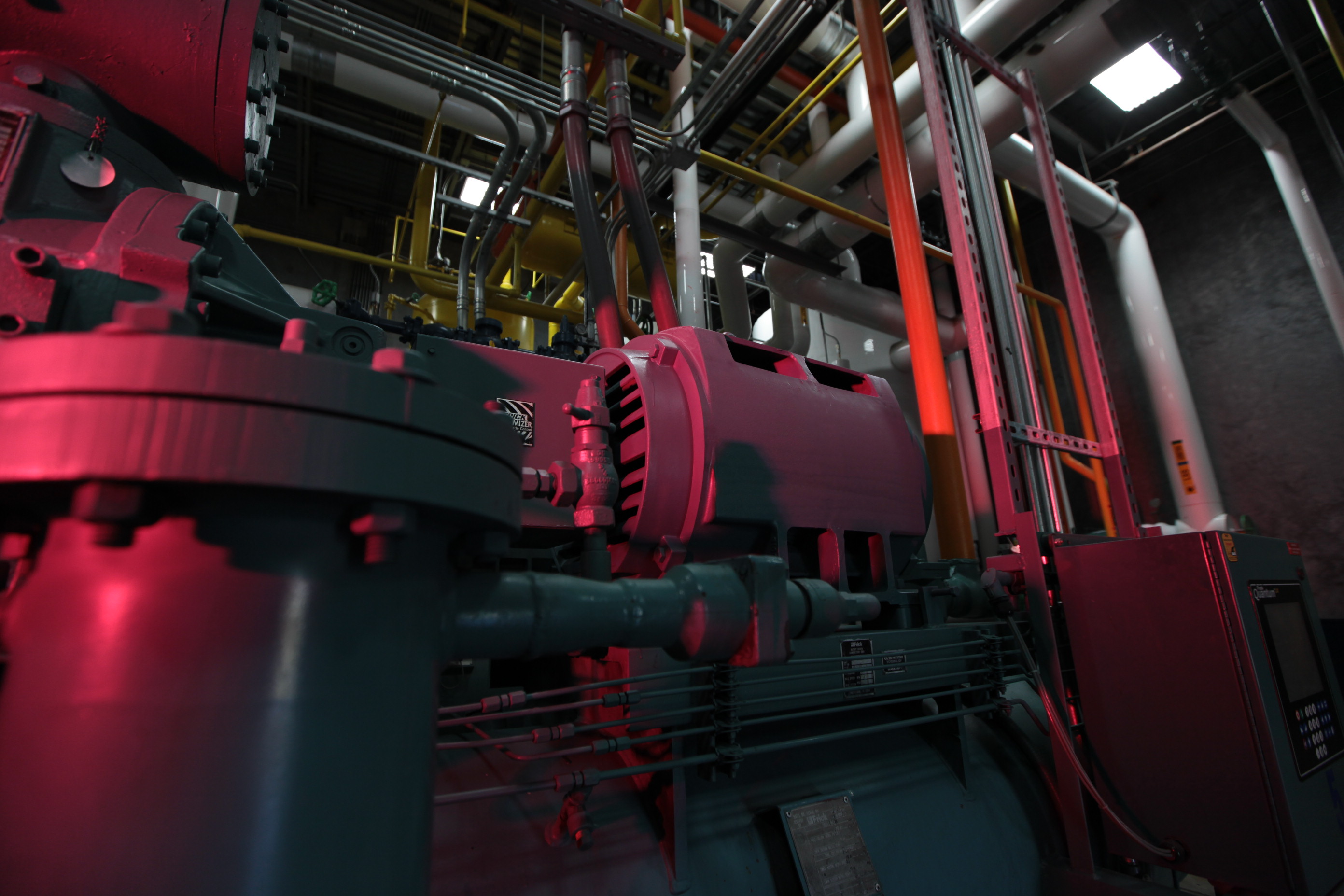

As Henry Kissinger said, “If you don’t know where you are going, every road will get you nowhere.” But how do we develop an effective roadmap when the industry is in a state of transformation? During our Food Engineering webinar last week, co-host Diane Wolf and I discussed the importance of a strategic plan when preparing for your food manufacturing business’ future.

Continue Reading “How to Evaluate Market Trends to Grow Your Food Business”

![[SlideShare] 5 Crucial Components Your Food Business’ Strategic Plan Must Include](https://stellarfoodforthought.net/wp-content/uploads/2016/06/Screen-Shot-2016-06-22-at-1.35.20-PM.png)

![How Does Your Food Business’ Strategic Plan Stack Up? [Downloadable Checklist]](https://stellarfoodforthought.net/wp-content/uploads/2016/06/Screen-Shot-2016-06-15-at-1.57.35-PM.png)