Two Approaches, One Goal: Reducing Your Ammonia Charge

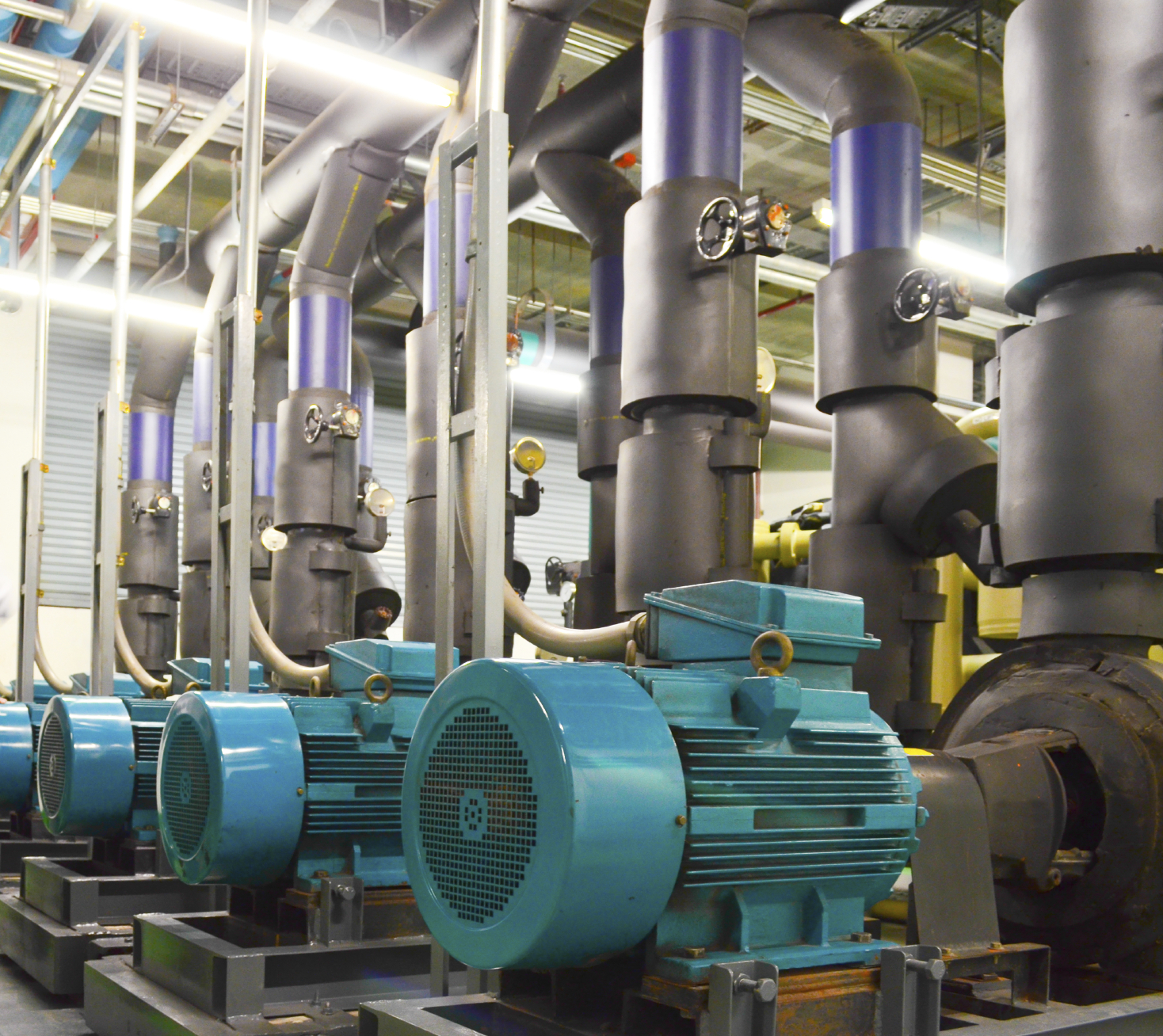

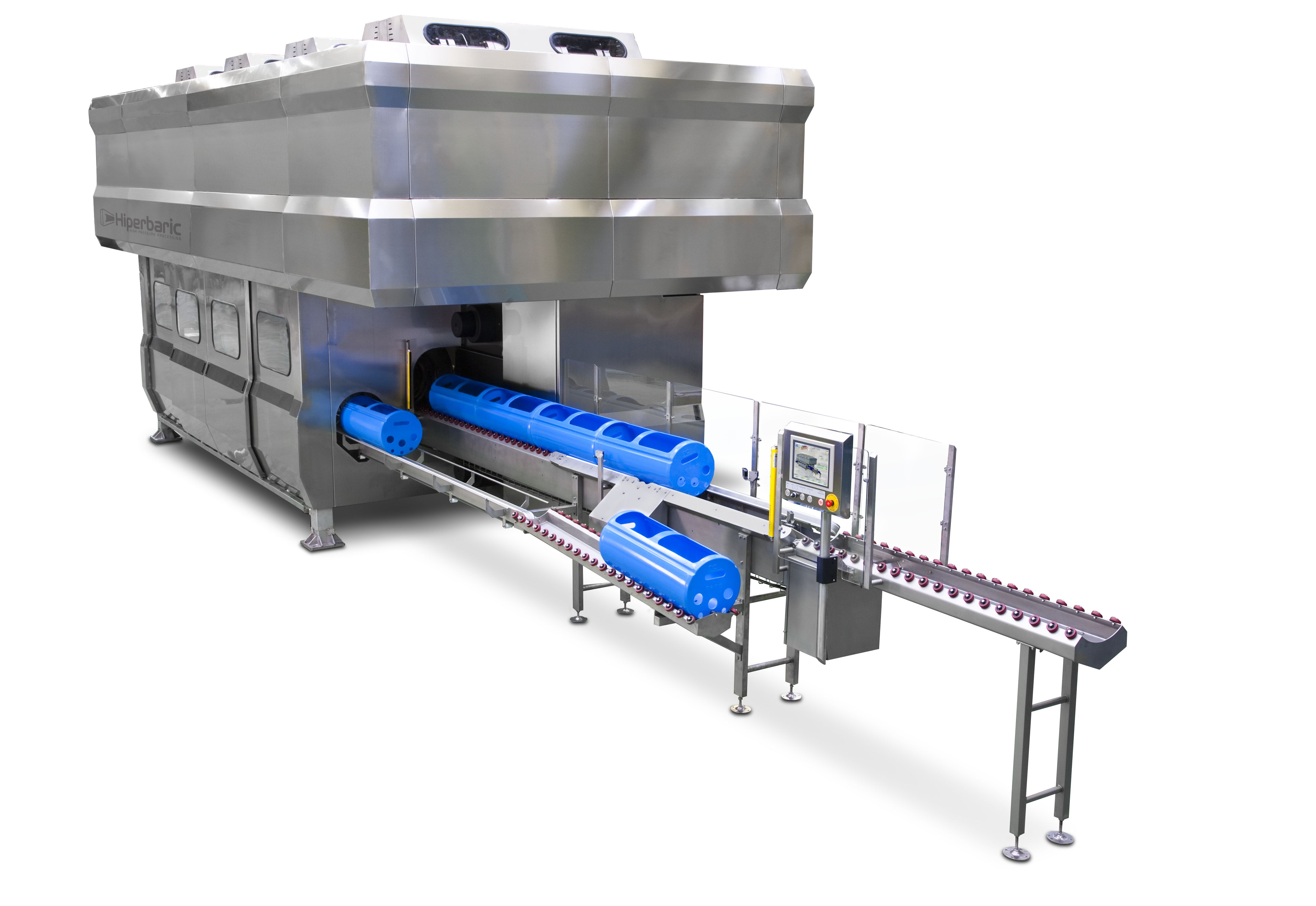

Efficiency and low cost are the major reasons ammonia is the preferred industrial refrigerant in the food processing industry. Ammonia is often a natural refrigerant and has no ODP/GWP. However, ammonia is a dangerous substance and there are several advantages to lowering the overall amount of ammonia used at a facility.

Continue Reading “Two Approaches, One Goal: Reducing Your Ammonia Charge”