Digital transformation is taking over the food industry. From automation and artificial intelligence (AI) to real-time mobile reporting, companies are looking to invest in digital tools that improve efficiencies and reduce overhead.

But with the wide variety of options available today, it can be difficult to decide which technological investment will keep your manufacturing facility ahead of the pack.

Simulation software is one of the newest technological breakthroughs – one that can save up to millions of dollars for food companies when they are building or expanding their facilities.

How simulations are changing the paradigm of process engineering and equipment layout

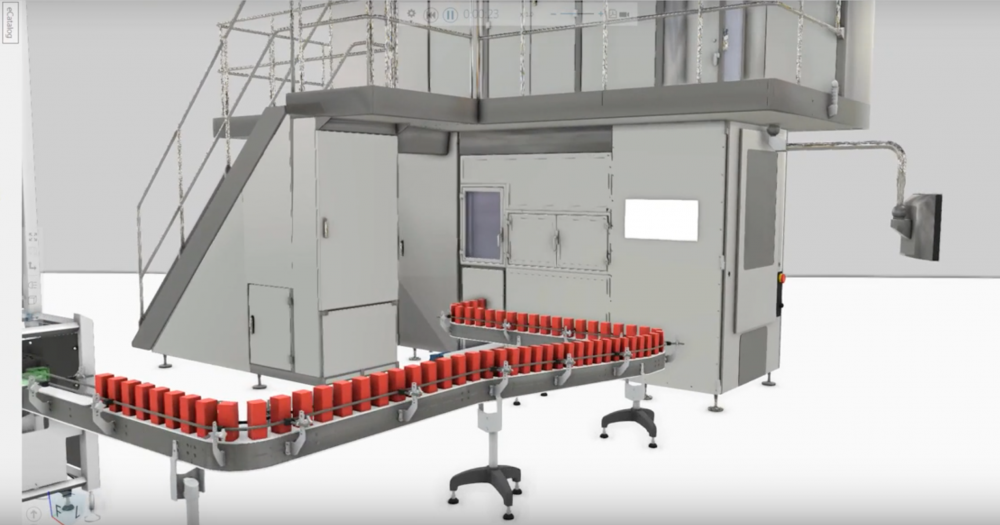

Simulation software allows you to design and run real-time 2D or 3D simulations depicting how food production lines or automated equipment will work. Within days, you can test dozens of scenarios to determine the most efficient design possible before any on-site work begins.

That means when it’s time for construction, you can fast-track your project rather than get stuck playing Tetris with your equipment.

Simulations are far more powerful than today’s industry standard – CAD layouts – because of the rich data you can input. While CAD layouts allow you to theoretically see how the plant will function, your team still has to estimate through points and choke points.

In contrast, simulations allow you to set real-life parameters using in-depth data, which makes it possible to accurately model realistic scenarios. Designers can pinpoint choke points and move a whole production line and supporting equipment around in minutes, versus spending real money on installation, hardware and new equipment.

Capabilities of simulation software

Dozens of simulation software options are available today, including providers like Simul8, PMC and FlexLink. Although they have differences, they essentially work the same way: You build a production system in the simulation, including all machinery, materials handling and human operators, and then run them in time-dependent scenarios.

Simulation software allows you to:

- Optimize and verify system capacity

- Optimize workflow and operator movements

- Test control strategies with virtual PLC I/O

- Change and test multiple line parameters, such as pitch between product, speed of conveyor belts, distance between pieces of equipment, etc.

- Calculate production metrics such as line OEE, which piece of equipment is the rate limiter, how many pallets you can ship per hour, etc.

- Optimize warehouse space and organization

- Find the best price point between high production and low overhead

- Identify bottlenecks and prevent costly material handling inefficiencies

- Create customized simulations by uploading your proprietary processes and systems into a library

- Train operators and engineers on a real-world production system using virtual tools

You can see what a line simulation looks like in this video:

One thing to note is that replicating employee behavior is more difficult because it’s less predictable. However, a major reason companies like to use simulations is they can see how to reduce/optimize labor, thus minimizing human error.

When to use simulation software

Simulations are utilized for both updating existing facilities and designing new ones. What information you need and how the simulations will work depends on the type of project.

1. Existing Facility

The software can help optimize your facility’s performance when upgrading or adding a new production line. Before running simulations, it’s critical that you assess the baseline for your current processes and identify any inefficiencies.

You can then test the difference an upgrade would make through simulating different scenarios. For example, you may test how much conveyor space is between equipment or whether an S-bend, curve-shaped or straight line works best considering the existing infrastructure.

Another way to optimize your plant’s performance is by modeling jams on different pieces of equipment due to different failure modes to see which ones cause the biggest loss of production in a single downtime event. This will help you plan maintenance and where your top priorities should be.

2. New facility

Simulation software can be an essential tool in designing your new facility. By identifying the optimal specifications, you not only save money in the short term by reducing construction costs but also increase revenue in the long term by enhancing your efficiency.

This is particularly true if you’re developing a greenfield plant where the relatively small cost of a simulation could save you millions of dollars. Refrigerated facilities, for instance, are typically built as a “big cold box” and filled as needed. But, if you know exactly what you require, you can design the layout accordingly. Your costs go down because you aren’t refrigerating unneeded space.

You can also use simulations to plan ahead. How big do you want to be in five or 10 years? It’s possible to simulate growth so that you can build the infrastructure for the future now.

Running simulations in-house vs. hiring a consultant

While food companies can purchase simulation software themselves, they may not reap significant benefits, because the results you get are only as good as the data you input. If your team doesn’t have the time or expertise to run 3D simulations, you likely won’t achieve much value.

That’s why consulting with an experienced design-build firm can help maximize your investment. For example, at Stellar, we have ready access to simulation software and the expertise on how to use it. Rather than paying for an expensive software license that may only last a few years, our clients only pay for the work completed.

By partnering with experts, you can discover if simulation software meets your company’s needs and how to optimize construction on your existing or new facility.

Have questions about simulation software? Comment below or email me at foodforthought@stellar.net.