When using ammonia refrigeration in a facility of any kind — whether it be meat or poultry processing, frozen food production or cold storage — compliance with ammonia safety standards is a must.

The International Institute of Ammonia Refrigeration (IIAR) is a membership-based technical society focused on ammonia refrigeration advocacy, education and standards. As an accredited American National Standards Institute (ANSI) Developer, IIAR establishes the minimum requirements for safely inspecting, testing and maintaining closed-circuit ammonia refrigeration systems.

IIAR 6-2019 was published in April of 2019 and is currently the most up-to-date standard for inspection, testing and maintenance. It provides detailed safety specifications to guide facilities and systems into compliance. These industry standards are a technical resource to ensure a safe and efficient industrial refrigeration environment. Some specifications covered in IIAR 6-2019 include:

- Offering a baseline for what you need to address and how often

- Minimum requirements for inspection, testing, and maintenance

- Recordkeeping for minimum safety requirements

- Being a part of an owner’s Mechanical Integrity Program, which serves as the management of critical process equipment to ensure it is designed and installed correctly, and that it is operated and maintained properly

- Serving as a GAP Analysis, to assist an owner with the evaluation of a project safety management program

IIAR 2- 2021 is the standard for the design of safe closed-circuit ammonia refrigeration systems. While IIAR 2-2021 and IIAR 6-2019 cover different areas of compliance, they overlap, and owners must be compliant in both. IIAR 2-2021 provided updates including:

- Changes to machinery room exhaust and ventilation based on new requirement

- Inclusion of emergency pressure-control systems, where required by authorities having jurisdiction (AHJs)

- Reorganized and clarified requirements for eyewash/safety showers

- New requirements for evaporators concerning design for freeze protection and design for frozen products

- Modified ammonia-detection requirements

Ensuring compliance despite supply chain disruptions

When a safety standard is updated, a facility may no longer be in compliance with IIAR Standards. In this case, the facility could face significant regulatory citations by allowing unsafe operation of the non-compliant system.

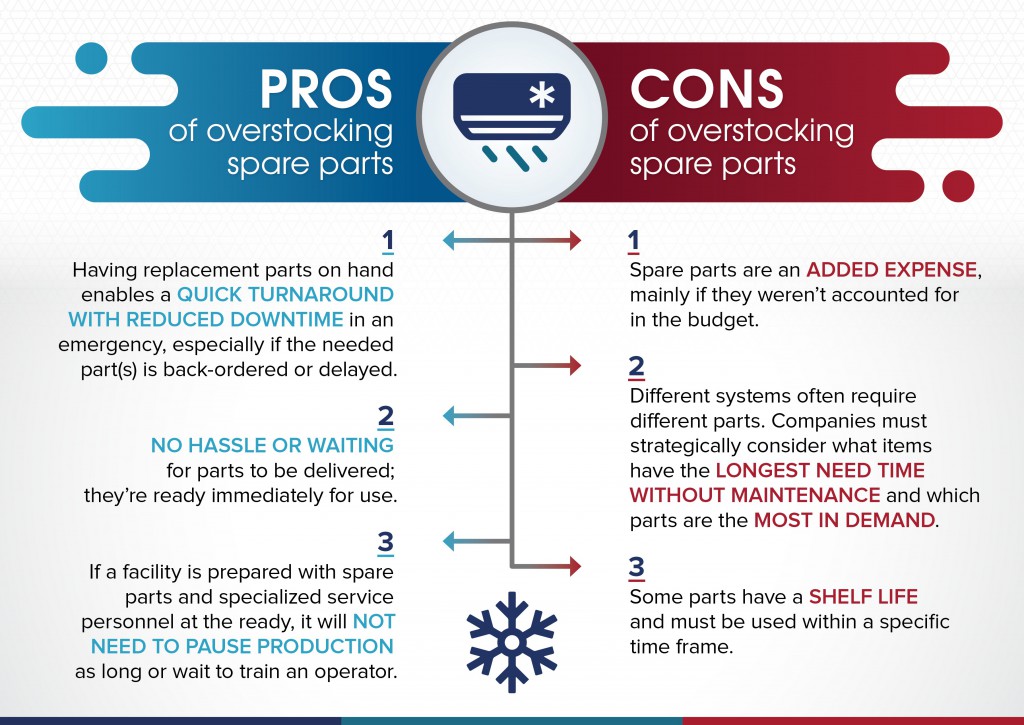

As inflation and overseas shipping delays persist, many manufacturers are still experiencing shortages. One proactive strategy to mitigate supply chain disruptions is stocking up on critical spare parts before you need them.

If you have concerns about what to stock, follow your original equipment manufacturer’s guidance on the life of your equipment and any warranty a part may have. It’s also essential to create a preventive maintenance schedule for your equipment, which will guide you on what parts you will need to keep your equipment running and in compliance.

Generally, we don’t recommend overstocking every single part, but instead, pick and choose the ones that will be most needed and create the least downtime. Stocking up ensures that you have the spare parts when an emergency arises. For example, safety relief valves must be replaced every five years, so it’s wise to keep replacements in your inventory. However, given current lead times, you may want to place those orders sooner than usual.

What parts should you overstock for IIAR 6 compliance?

In general, maintain a generous supply of common wearable parts for long-lead refrigeration control valves, such as bonnets and spare motors/solenoids. Due to shortages in electrical components, you should also stock spare refrigeration control panel boards, modules and sensors.

Whenever possible, buy similar equipment to what you currently have. This is a good way to maintain parts on hand because the same parts can be used in an emergency and keep your inventory cost low. Some facilities use systems that automatically reorder parts when one is taken out of inventory. This kind of automated solution may be a worthwhile investment for your facility.

Make compliance and PSM a breeze

Stellar’s Aftermarket Services can assist with any situation your facility may face.

Some systems fall out of compliance when building codes are updated or when there is a change in recognized and generally accepted good engineering practices (RAGAGEP). In these situations, Stellar can provide a turnkey design experience that can determine an optimized solution.

Our Refrigeration Parts team helps manage long lead times by stocking the most commonly needed parts, and our Refrigeration Services group troubleshoots and determines your exact needs. Meanwhile, our Compliance team can develop a process safety management (PSM) program, provide planned maintenance alerts, and help your team prepare for regulatory agency audits. When appropriate, Stellar’s Compressor Services can also rebuild your worn compressors and provide extra life to the heart of your refrigeration system before completely replacing them.

Compliance is ultimately about safety, and that makes it a priority. In today’s market, you must be proactive and prepared to minimize downtime and keep your ammonia system compliant and running smoothly.

Have questions about keeping your facility compliant with IIAR safety standards? Email us at foodforthought@stellar.net or give us a call at 800.488.2900.