Americans have been quitting their jobs in record numbers since the onset of the COVID-19 pandemic. The so-called Great Resignation is significantly impacting the food and beverage industry. In response, many industry leaders are focusing on ergonomics strategies to improve employee comfort and safety, and in turn, retention.

“If the workplace is designed to meet peoples’ needs, it demonstrates the employer’s commitment and enables employees to be fully engaged in the workplace,” says Jeff Sanford, an ergonomics expert at VelocityEHS, a provider of environmental health and safety (EHS) solutions.

Sanford recently spoke at a webinar hosted by Food Processing magazine, in which he shared best practices for improving ergonomics and employee safety within the food and beverage industry.

The goal of ergonomics is to prevent soft-tissue injuries and musculoskeletal disorders (MSDs) caused by sudden or sustained exposure to force, vibration, repetitive motion and bad posture. This is especially important in the U.S. food and beverage industry, which has the highest lost-workday incidence (LWDI) across all industries with a rate of 6.5 injuries and illnesses per 100 full-time workers, compared to the standard of 3.3.

These numbers especially matter in today’s competitive labor market. A recent study on ergonomics cited in the webinar found employee turnover dropped anywhere from 23% to 49% within companies that employed an ergonomics strategy. Meanwhile, the same study found absenteeism dropped between 42% and 116%. These statistics could help some processing facilities justify the cost of implementing ergonomic changes.

What can facility owners and plant managers do to improve employee ergonomics? Below are some common issues and solutions shared during the webinar.

Common workplace tasks that can be safety hazards

- Standing workstations with no adjustability in posture (common in packing)

- Workers reaching too far or too low

- Employees lifting products that are too heavy (can be subjective but there is data to guide limits)

- Improper handling of raw materials

- Staffing shortages cause employee exhaustion, leading to more human error

- Pushing, rather than pulling carts, when sight lines are obstructed

- Using poorly designed equipment

Ergonomics solutions for food plant safety hazards

- Avoid repetitive movements

- Shorten shifts to reduce employee fatigue

- Ensure employees aren’t standing/working in uncomfortable positions

- Reduce or automate strenuous tasks

- Employ pallet lifts and replace manual feeding with vacuum conveying whenever financially viable

- Ensure employees have proper PPE and functioning standard equipment

- Keep push/force of transporting carts within acceptable limits

- Ensure workers are walking on a non-slip surface

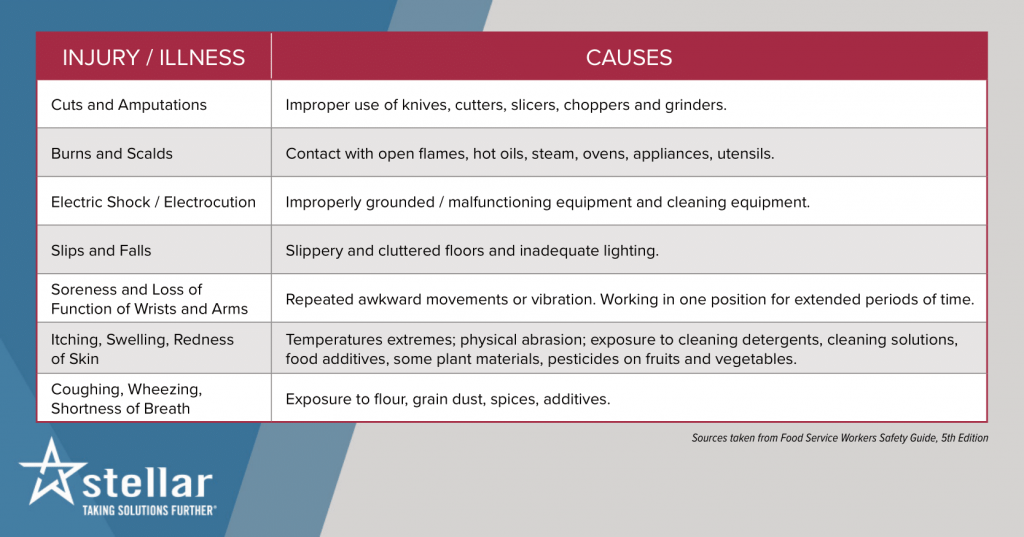

While a 100% injury-free workplace is an ambitious goal, a facility can come close by understanding how incidents happen and taking steps to prevent them. Let’s examine common food processing plant injuries and their causes:

“Ergonomics, when done right, improves both employee well-being and your business performance. When ignored, injuries, absenteeism, quality defects, productivity lags and other issues could arise,” says Dave Fusaro, Editor in Chief of Food Processing.

Accidents can result in company-paid leave, higher insurance premiums, decreased productivity and increased employee turnover rates. The current labor shortage is making it more important than ever for facilities to retain their employees by providing them with a safer and healthier work environment.

Designing Bell & Evans’ award-winning facility with employee welfare at the forefront

While conceptualizing its award-winning chicken harvesting and processing facility, Bell & Evans, a pioneer in the poultry industry, turned to Stellar for its expertise in designing and constructing food processing facilities for some of the biggest names in the industry.

Bell & Evans recognized that working in a food processing plant takes grit. It’s why some leaders in the industry refer to workers as “industrial athletes.” So, when Stellar designed their state-of-the-art organic chicken harvesting facility in Fredericksburg, Pennsylvania, the team sought to create an environment fit for industry pros.

Employees at the facility have access to benefits any skilled athlete would rely upon before a big game. For instance, Bell & Evans employs athletic trainers that assist with warmup and stretching routines, ensuring team members circulate through different movements to avoid repetitive stress injuries on the plant floor.

The 411,500-square-foot facility also has an on-site health clinic staffed by nurses where employees can access basic health exams and medication. It also has an off-site wellness center for all team members and their families to utilize with no copays or deductibles.

Additionally, Bell & Evans employed many new automation processes to reduce workplace injuries, including the following:

- Live receiving — The automated live receiving transport system eliminates the need for noisy, jolting fork trucks. It minimizes human touchpoints, increases team member safety and reduces physiological stress experienced by the birds upon arrival. After they are humanely rendered unconscious via slow-induction anesthesia (SIA), the chickens are harvested.

- Bird grading and tracking — Once the birds are plucked, they pass through a series of cameras programmed to spot certain variables in the raw, whole chickens and flag them to be removed from the line for human inspection. The system also tracks which farm each bird originated from, improving traceability and aiding Bell & Evans in evaluating and improving individual grower performance.

- Byproduct vacuum system — In the plant’s harvest area, a waste vacuum system automatically collects and transports byproduct material to the nearby company-owned rendering facility for disposal or to be sold as-is to pet food facilities for future processing. The system eliminates the need to manually transport the material, thereby improving the facility’s cleanliness and efficiency.

- Deboning and X-ray bone detection — Once the raw, whole birds enter the cut-up and debone area, they undergo automated dark meat deboning, which further reduces team member touchpoints and improves food safety. All of the boneless, skinless white and dark meat passes through X-ray bone detection equipment originally designed for the fish industry to identify even the smallest bones.

- Case delivery — An empty case delivery system efficiently places bulk packing stations around the cut-up room. The technology is not typically found in similar facilities due to the expense of implementing the length of conveyance required. This system streamlines Bell & Evans’ packaging process and eliminates manual case delivery.

- Packaging — The thick tunnels, dock equipment and dock are outfitted with all the necessary infrastructure to support the use of automated guided vehicles (AGVs). Eleven robots automatically pack and palletize products in the warehouse, eliminating human interaction. The innovative design includes space for robots to be added, so the facility can operate as ergonomically and efficiently as possible.

- Chemical delivery — Organic-certified cleaning solutions are automatically piped to various distribution points throughout the facility. The system monitors electronic signals within the conduits and regulates control valves to ensure proper delivery with no human contact.

5 steps to prevent musculoskeletal disorders on the plant floor

An internal or external audit of musculoskeletal disorders can help identify which safety issues are most prevalent at your facility so you can correct them.

- Determine your facility’s current needs by performing an internal audit and identifying areas that need improvement. This should include surveying employees for their input.

- Establish plans for an improvement process

- Gain leadership commitment by identifying roles and responsibilities for individuals and creating a team to handle ergonomic changes.

- Launch and sustain improvements by implementing approved changes.

- Track your progress by recording and examining data. These metrics can be powerful proof points for the program’s success.

While major automation investments are not cheap, most ergonomic changes are relatively easy to complete and require little budgetary approval. Putting into practice the aforementioned tips can greatly impact workplace safety and morale. Though it may not be possible to avoid all workplace injuries, there are plenty of practical solutions food processing plants can implement to significantly reduce the number of mishaps that occur on the job.

Are you looking to incorporate employee wellness into your new or existing facility’s design? Email us at foodforthought@stellar.net or give us a call at 904.260.2900.