There are more than 68,000 pork producers in the United States alone—competition is fierce. So how can your hog facility remain competitive? By producing the highest quality product possible for consumers, efficiently. And an effective chilling system is key to facilitating the most premium product for your consumers: a flavorful cut of meat with appealing color, firmness and moisture levels. The faster a carcass is cooled after slaughter, the better quality the meat will be. Quick chill systems, specifically, reduce chill time and produce a better cut of meat. While they may be a significant upfront investment for your food plant, this method offers significant advantages and long-term ROI.

The old way: traditional hog coolers

Before diving into quick chill systems, let’s examine the most popular chilling method for pork producers: traditional hog coolers.

After the hog is slaughtered, it is put into the cooler for 24 hours to remove the heat. Pig carcasses must reach a temperature of 39.2°F prior to further processing. The faster the internal meat temperature decreases, the better the meat quality is preserved.

However, during those 24 hours the meat begins losing moisture and weight as it cools (this is an experience called “shrink”). For an industry built on a weight-price model, weight lost is money lost.

For medium- to large-sized facilities, reducing shrink by even 1 percent can save your business money.

The better way: quick chill cooling systems

Just as its name suggests, quick chill cooling systems are designed to quickly chill hog carcasses. These rapid chill systems are designed to remove approximately 98 percent of the heat from the hog carcasses as quickly as possible, before the meat enters the hog coolers.

When a carcass is processed in a quick chill system, it is chilled for a period of 90 to 120 minutes before it is moved to an equilibration cooler. Straight out of the quick chill system, the center of the meat is around 80℉ while the outside is frozen. A cooler, referred to as the “equalizing chill,” then evens out the meat temperature. Dwell time in the equilibration cooler is typically 18 to 24 hours.

3 ways quick chilling improves pork quality

Facilities that use quick chill are able to see huge ROIs by reducing shrink and appealing to higher-quality markets.

Did you know the U.S. exported over 2 million metric tons of pork in 2015? Most of the countries that purchase this product, like Japan, are primarily interested in premium pork cuts. Rapid chill systems allow plants to produce product of this caliber.

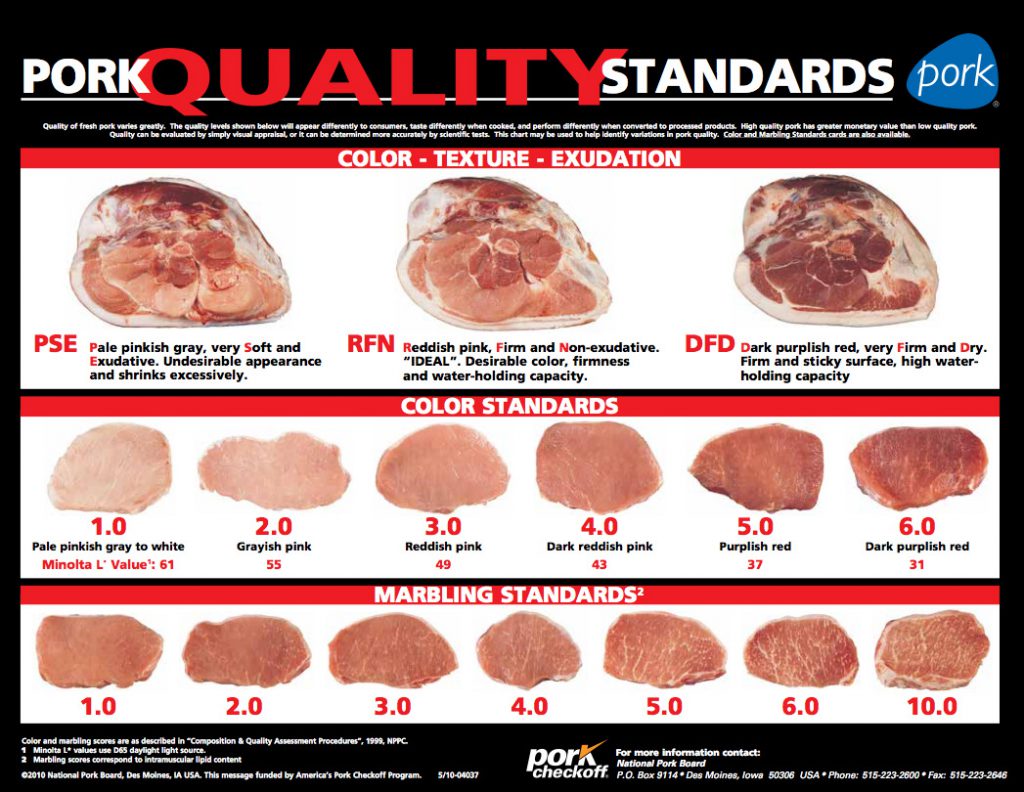

Remember, pork quality is determined by:

- Color

- Firmness

- Exudative (moisture leaving the product)

Here are three benefits rapid carcass chilling offers with product quality:

1. Darker meat color—Quick chilling helps reduce the occurrence of PSE (pale, soft and exudative) meat. Pale muscle can quickly turn gray when in a retail display case, presenting an undesirable appearance.

2. Desirable taste and texture—Slow chilling can produce wet muscles, creating a soft product. A soft product has a tendency for shrinkage during processing due to moisture loss, producing a dry tasting product after cooking. Rapid chilling cools meat quickly, reducing shrink and moisture loss, and improving taste and texture.

Source: The Pork Store Checkoff

3. Safer product—Research from European pork plants shows quick chill systems reduce bacterial contamination and extend the shelf-life of the product.

While you may have a better understanding of the benefits of quick chill systems, it’s important to remember they can only be achieved if your system is designed correctly. Come back to Food for Thought next week for my post on quick chill design best practices.

Stellar applied the above best practices when designing a quick chill system for Maple Leaf Foods. Learn more about this plant here.