Many food distribution warehouse owners rely on a proven “ceiling only” fire protection system designed specifically for cold storage facilities. The Quell™ Fire Sprinkler System (K17), developed in 2006, has quickly become an industry standard for cold storage warehouses — and for good reason.

What sets Quell apart?

The advanced Quell™ system uses a “surround and drown” approach to rapidly control a fire using a large volume of water. This not only puts out the fire quickly, but also reduces heat and minimizes damage to the distribution facility itself and to its contents and products.

When a sprinkler is activated, water is discharged on a delay to allow time for one or more additional sprinklers to be thermally activated by the fire, ensuring sufficient water volume and cooling is applied to control it before it can spread. Developed by Tyco Fire & Building Products, this system should only be installed by licensed contractors.

The K17 Quell™ Fire Sprinkler System allows for building heights up to 48 feet and storage limited to 40 feet. In 2016, a new Quell™ Fire Sprinkler System (K34) was introduced that allows building heights up to 55 feet with storage limited to 50 feet. The K34 Quell™ Fire Sprinkler System still revolves around the “surround and drown” approach with almost double the amount of water being discharged per sprinkler head. It has also been tested and approved by Factory Mutual.

Benefits for refrigerated facilities

Quell™ systems offer many advantages for cold distribution warehouses:

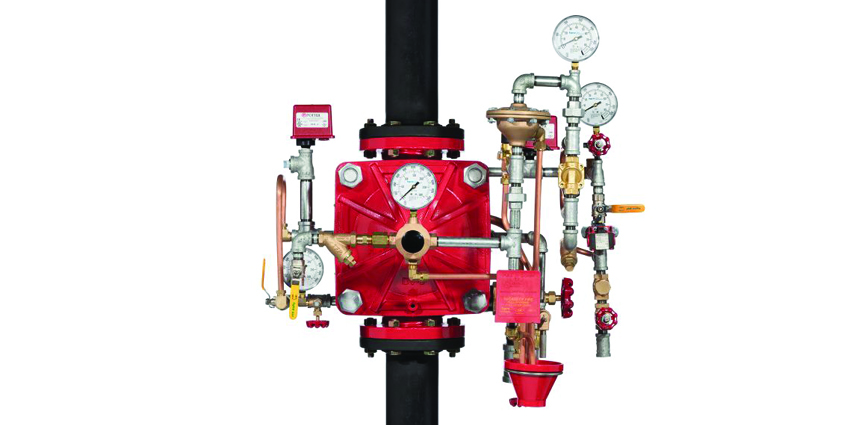

1. Double interlock preaction

As a double interlock preaction system, there are two separate events required before water can be introduced into the supply piping. The system consists of linear heat detection cabling that is set with a lesser temperature rating than the sprinklers and sprinklers installed on the branch line piping. In either sequence, the linear detection AND a sprinkler head must be activated. Inadvertent operation of only the linear detection OR an automatic sprinkler (incidental damage or malicious activity), will not allow water to enter the supply piping.

2. Class range protections

The K17 Quell™ system provides fire protection for Class I, II, III, IV and Group A plastic commodities. This means frozen foods, foods in plastic or even combustible containers are protected, including certain alcoholic beverages and a wide range of other goods and various containers. The K34 Quell™ Fire Sprinkler System provides fire protection for Class I, II, and III commodities, which includes frozen foods packaged in plastic trays and stored in cardboard boxes.

3. Less expensive to install, operate and maintain

The system’s pipes are only located in the ceiling, so they’re less expensive to install than costly in-rack installation. In addition, the sprinklers are easier and more cost-effective to maintain compared to in-rack sprinklers, which are more easily broken by pallets and forklifts. You’d really have to go out of your way to break an overhead sprinkler head with a Quell™ system.

4. Flexible storage

Since the sprinklers are located in the ceiling, roof and storage heights can be higher, allowing the facility to utilize more flexible stocking configurations.

5. 10-year warranty

To top it off, the Quell™ Fire Sprinkler System is backed by an industry-leading 10-year limited warranty.

If you’d like to learn more about the Quell™ Fire Sprinkler System and how to protect your cold storage facility, email us at foodforthought@stellar.net and vhumphreys@ahernfire.com

What is the minimum area requirements to be applied on pre action double interlock prea-action valve?

Hi, Edilberto. Thanks for reading! There are many different applications that utilize double inter-lock systems, so I recommend researching NFPA, local jurisdiction requirements, and manufacturer requirements and recommendations. -Vince