Did you know that compressed air systems can be a source of contamination in your food plant? Dangerous bacteria and pathogens can be difficult to spot in your facility—especially if they are airborne. It’s a common misperception that compressed air is considered as clean as the air from the outdoor environment that surrounds your facility—NOT true. Once in the compressor, the air outside of your facility (ambient air) mixes with other elements within your compressor (i.e., corrosion, worn seals). Whatever is not caught in your filtration system is then circulated throughout your plant.

Contaminants in compressed air can damage your product through direct or indirect contact. How? Microorganisms travel through the air and can cause changes in your products’ color and taste and even reduce shelf life. Keeping your filtration system clean can eliminate the hidden creatures that may be lurking in your plant’s air system.

What is in your compressed air?

The air in your plant is ambient air that has been compressed and then filtered through your facility. Because it comes from outside, this air contains:

- Microorganisms

- Liquid oil

- Oil aerosols

- Oil vapor

Note: Oil that is compressed with your air can contain vapors from surrounding car and industrial exhausts.

Particles pulled in with your air can leak through your air system’s cracks and weak spots within the compressor. These might include:

- Worn seals

- Orifices

- O-rings

Because compression raises the temperature of the air, water vapor is used as a cooling agent. This vapor can produce rust and corrosion that mixes with the air that is then filtered throughout your facility. Water condensate and warm compressed air provide an ideal environment for microbiological growth, spores and mold.

How can you detect contaminated air?

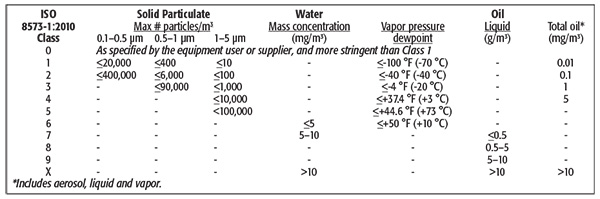

There is currently no regulatory standard for the minimum cleanliness of compressed air in food plants. The most common standard regarding compressed air is ISO8573.1-2010 from the International Standards Organization (ISO). The specifications for the air standard can be seen in the table below.

Source: Food Safety Magazine

Source: Food Safety Magazine

2 ways to prevent contaminated air in your food facility

1. Keep the air as dry as possible—Before pumping the air through your plant, remove as much moisture as possible. The ideal dew point is -40℉. Most facilities have a large dryer that can achieve this level of dryness. Monitor your dryer’s performance regularly to ensure that it can reach this temperature specification.

2. Use at least a two-stage filtration system—Ensure your facility is using proper filters to prevent microorganisms appearing in the air and traveling through your plant. Food Safety recommends installing a two-stage filter system as close as possible to the point of use. For some plants, a three-stage filter system may be necessary.

Remember: not all filters are equal. HEPA filters are high-efficiency air filters that are up to 99.99 percent effective at catching particles as small as 0.03 microns. However, the microorganisms that can travel through your air system and contaminate your food are even smaller. To ensure contaminated compressed air is not flowing through your plant, install a filter at the final stage of point-of-use filtration that has a rating of 0.01 micron with a 99.99 percent efficiency rating. Look for air filters that continuously drain liquids and can catch microorganisms and oils.

Investing in a strong filtration system can lead to contaminate-free air, resulting in improved shelf life, reduced recalls and enhanced food quality and safety. A clean compressed air system keeps your entire food facility safe and healthy.

Plant owners must be sure to regularly monitor dryers and air filters, and take preventative measures to eliminate contaminates in the air.

If you would like to learn more about preventing contamination in your compressed air system, email me at foodforthought@stellar.net.