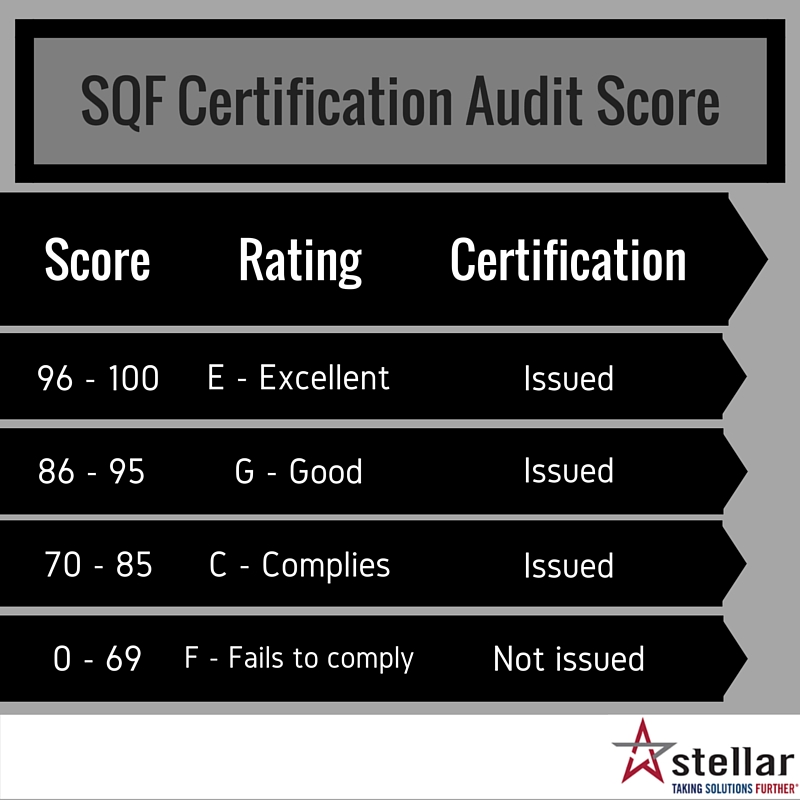

An Overview of the Safe Quality Food (SQF) Certification Audit Process

Last week, we outlined the basics of a Safe Quality Food (SQF) certification, examining the benefits, costs and the steps. However, the biggest piece of this food safety certification is passing the actual audit. Here, we provide a comprehensive look at the initial SQF certification audit process, including the time frame and scoring parameters.

Continue Reading “An Overview of the Safe Quality Food (SQF) Certification Audit Process”

![[Infographic] 4 Steps in Developing a Manufacturing Plan](https://stellarfoodforthought.net/wp-content/uploads/2015/10/4-steps-in-developing-a-manufacturing-plan.jpg)