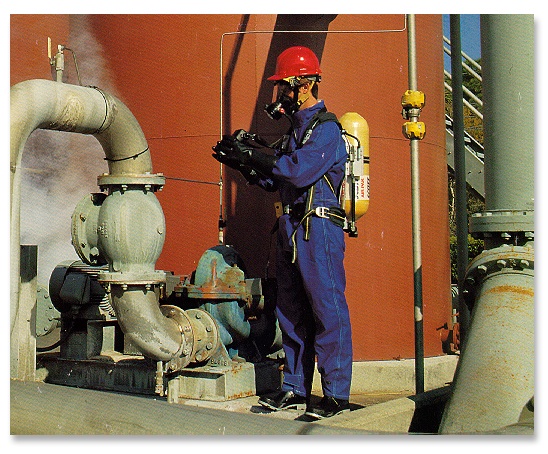

Three Reasons to Consider a Behavior-based Approach to Worker Safety

In last week’s post, I introduced you to the behavior-based approach to worker safety. While ergonomic design and regulatory compliance remain critical to worker safety, behavior-based safety strategies incentivize employees to take ownership of their own safety. Employees proactively identify potential hazards, helping prevent them from ever happening in the first place.

Below, I outline in more detail three reasons you should integrate a behavior-based approach into your food plant’s worker safety practices.

Continue Reading “Three Reasons to Consider a Behavior-based Approach to Worker Safety”

![[Infographic] 4 Steps in Developing a Manufacturing Plan](https://stellarfoodforthought.net/wp-content/uploads/2015/10/4-steps-in-developing-a-manufacturing-plan.jpg)

![[Infographic] Factors That Influence Cold Storage Warehouse Cost Savings](https://stellarfoodforthought.net/wp-content/uploads/2015/09/Infographic-Factors-That-Influence-Cold-Storage-Warehouse-Cost-Savings.png)