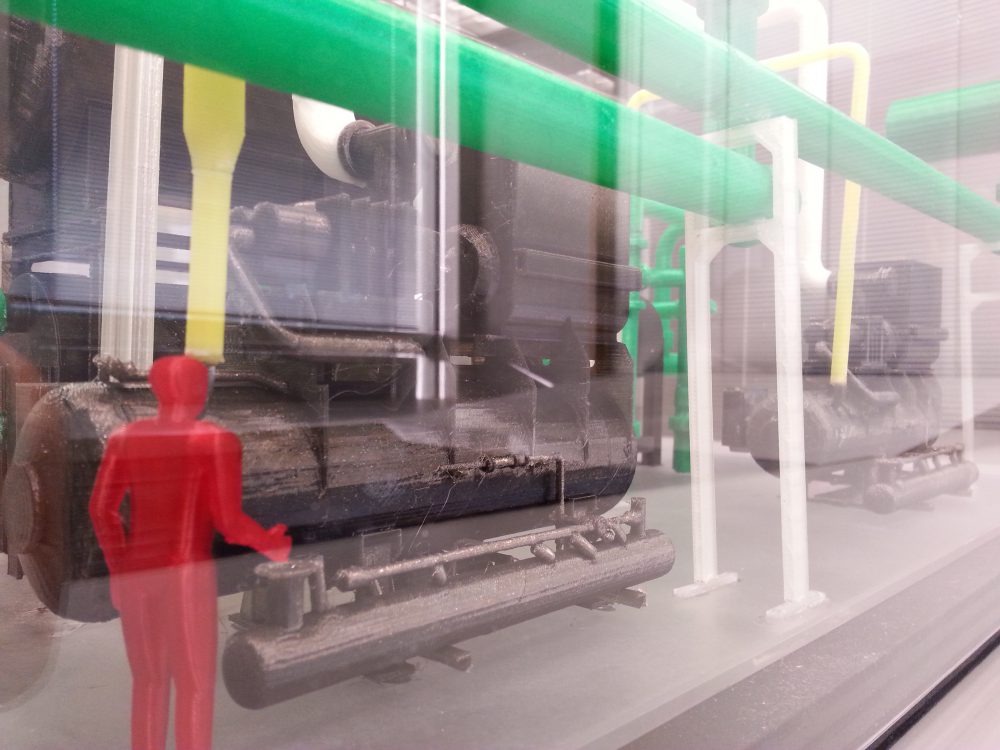

How 3D Printing is Complementing the Refrigeration Design Process

Headlines have been hot with 3D printing news, toying with opinions on how the technology could affect the everyday consumer experience. At Stellar, we’re seeing the value of 3D printing firsthand. For over a year now, we’ve been using 3D printers to provide our refrigeration clients with 3D models they can touch and feel–and it has proved to offer benefits for both sides of the table.

Continue Reading “How 3D Printing is Complementing the Refrigeration Design Process”