Food Plant Emergency Response: What to Do After a Hurricane

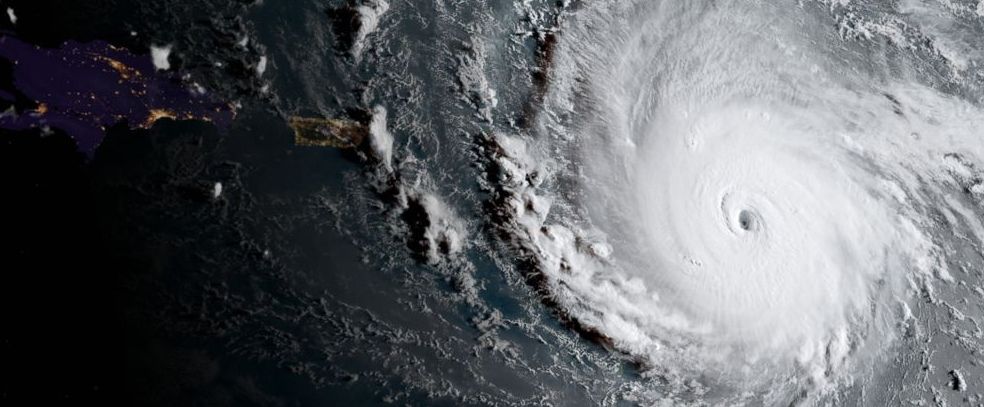

Hurricane Irma (photo source: ABC News)

The state of Florida, the Caribbean and portions of the Southeastern U.S. are reeling from the impact of Hurricane Irma this week. The deadly storm brought damaging winds and torrential rain to the entire Sunshine State, including our headquarters in Jacksonville.

We’re now more than halfway through the 2017 Atlantic hurricane season, and with more than 11,000 food and beverage manufacturing plants in hurricane-susceptible states on the Gulf and Atlantic coasts, it’s critical to plan for the damage a hurricane can bring.

Continue Reading “Food Plant Emergency Response: What to Do After a Hurricane”