6 Ways to Optimize Your Refrigeration Efficiency and Lower Energy Costs

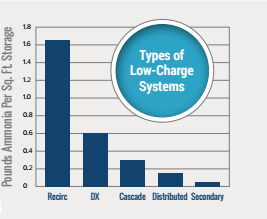

Did you know that up to 60 percent of a manufacturing facility’s total operating expenses comes from industrial refrigeration? It’s no surprise that refrigeration efficiency is a priority.

However, engineers often look to optimize individual components rather than taking a holistic approach, leading to wasted energy and operational inefficiencies. To avoid this fragmented approach, here are six steps to optimize the entire system and achieve the greatest energy efficiency:

Continue Reading “6 Ways to Optimize Your Refrigeration Efficiency and Lower Energy Costs”