There were a total of 440 recalls of FDA and USDA regulated food products in 2017.

The single leading cause of recalls last year? The presence of undeclared allergens and the misbranding of products.

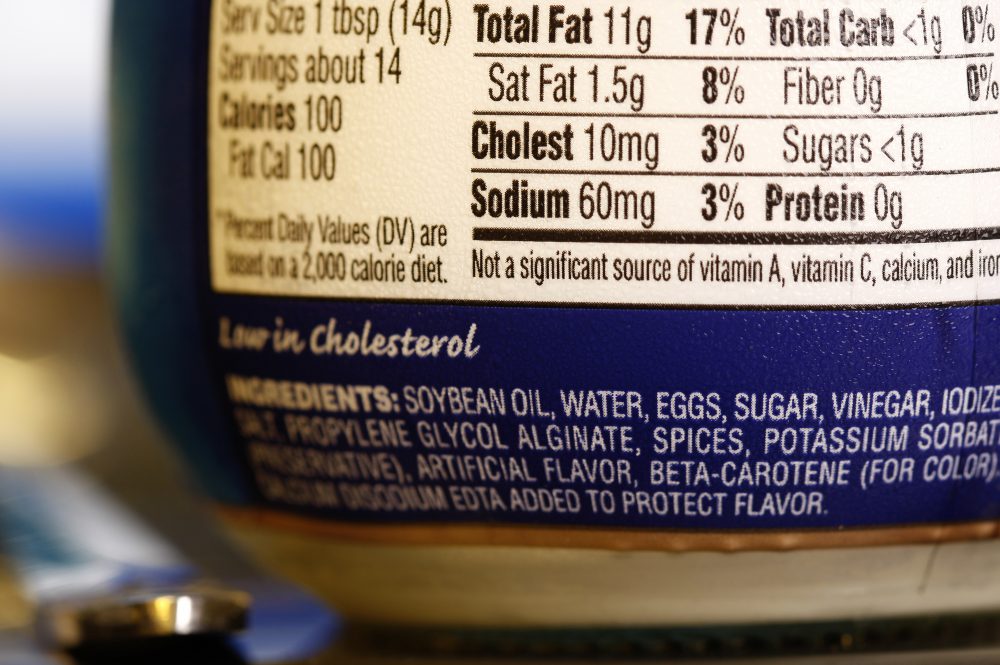

A total of 218 recalls (nearly half of the total) were announced because a product contained ingredients that weren’t declared on the label, such as:

- Egg

- Fish

- Milk

- MSG and/or sulfites

- Peanuts

- Shellfish

- Soy

- Tree nuts

- Wheat

So how can you reduce the risk of a costly recall and avoid being a part of this year’s statistic? Let’s look at a few things your business can do from the plant floor to the label design process.

1. Barcode scanners and vision systems

Many recalls stem from mispacks, when the product is packaged in an incorrect container. This can happen if a wrong roll of packaging film is used to pack a product (often because its graphics look similar to another product’s packaging) or if primary packaging (like an individually wrapped pouch) gets put into the incorrect secondary packaging (the carton).

This is a prime scenario for a recall, especially if an allergen is involved. For example, if pouches of cinnamon-almond oatmeal (allergen) are packaged in cartons for a cinnamon-raisin oatmeal (no allergen), you could have a big problem on your hands.

Many times these errors can be caught on the line by barcode scanners or vision systems. These tools can read barcodes on primary and secondary packaging to confirm that the right products are going into the right packaging.

Having this technology as a checks-and-balances measure can reduce the risk of error during changeovers. If the carton manufacturer puts cartons for Product A into a case labeled for Product B, your plant staff may load the wrong cartons into the magazine if they don’t catch the difference — meaning the product in that run would end up in incorrect packaging.

However, barcode scanners and vision systems can serve as a failsafe in this scenario to ensure that the correct packaging is loaded with each production run. If there is a mismatch, the tools will detect it, reject the carton and even stop the line.

You can add additional provisions by installing barcode scanners to scan ingredients coming to the line, ensuring the correct ingredients are going into a process during production.

2. Good manufacturing practices (GMP)

It’s critical to establish good manufacturing practices throughout your facility from the production floor on up, for example:

- Clear the entire line when a changeover occurs

- Before starting up again, run the new product once and make sure the correct primary and secondary packaging is being used

- If the product and packaging checks out, sign off on it and proceed

Some manufacturers take the extra step of then taking that test run product to the quality assurance (QA) department to be opened, inspected and tasted.

3. Have dedicated lines for allergen products

When possible, it’s ideal to run allergen and non-allergen products on separate production lines or production lines in separate rooms. (Some manufacturers even produce them in separate facilities altogether.)

Having dedicated lines reduces changeovers, meaning you don’t have to clean the entire line before and after each product. Of course, proper cleaning and sanitation is important no matter what, but separate lines takes things one step further in avoiding potential cross-contamination.

4. Solidify the chain of approvals for packaging design

Many allergen-related recalls aren’t even the result of a mispack — they are often caused by an oversight in the packaging design process, before the product even reaches the line. Before graphics end up on packaging that makes it to the plant floor, the design should be approved by several people from various departments, including:

- Food Technology

- Graphic Artist

- Marketing

- Packaging Engineering

- Procurement

- Production

- Quality Assurance

- Regulatory

- Research & Development

It’s crucial to have a solid process in place for approving this packaging, since one slip-up can trigger a costly recall. The Food Allergen Consumer Protection Act requires that allergens are listed both in the ingredients list and in the dedicated section that warns of allergens (“Contains: Peanuts”). I’ve seen recalls happen because an allergen was listed in one place but not the other — a seemingly simple, yet costly mistake.

Another potential issue is the use of incorrect terminology such as declaring “flour” but not “wheat” on the packaging. The listing of allergens is heavily regulated by the Food and Drug Administration (FDA), so solidifying the chain of approvals for your packaging is a must to reduce the risk of a recall.

5. Know your supplier

Finally, it’s important that you are certain of the ingredients you receive from your supplier, especially if you’re switching to a new supplier.

Many recalls result from a failure to carry over allergen information from a supplier and sometimes these can catch you off guard. For example, a fish processor once sourced flour from a new supplier, but didn’t realize that supplier used milk in producing their flour.

Don’t cut corners when it comes to paperwork and double-checking ingredients from suppliers. Having a thorough process in place may save you from a recall in the future.

Have questions about allergen control and product packaging? Email me at foodforthought@stellar.net