So you want to incorporate artificial intelligence and machine learning into your food processing facility — but where do you start? These tools have grown increasingly popular, and you’ve likely heard people discussing different platforms like Amazon Web Services (AWS), Google Cloud and Microsoft Azure. But how do you get access to these tools and what can they do?

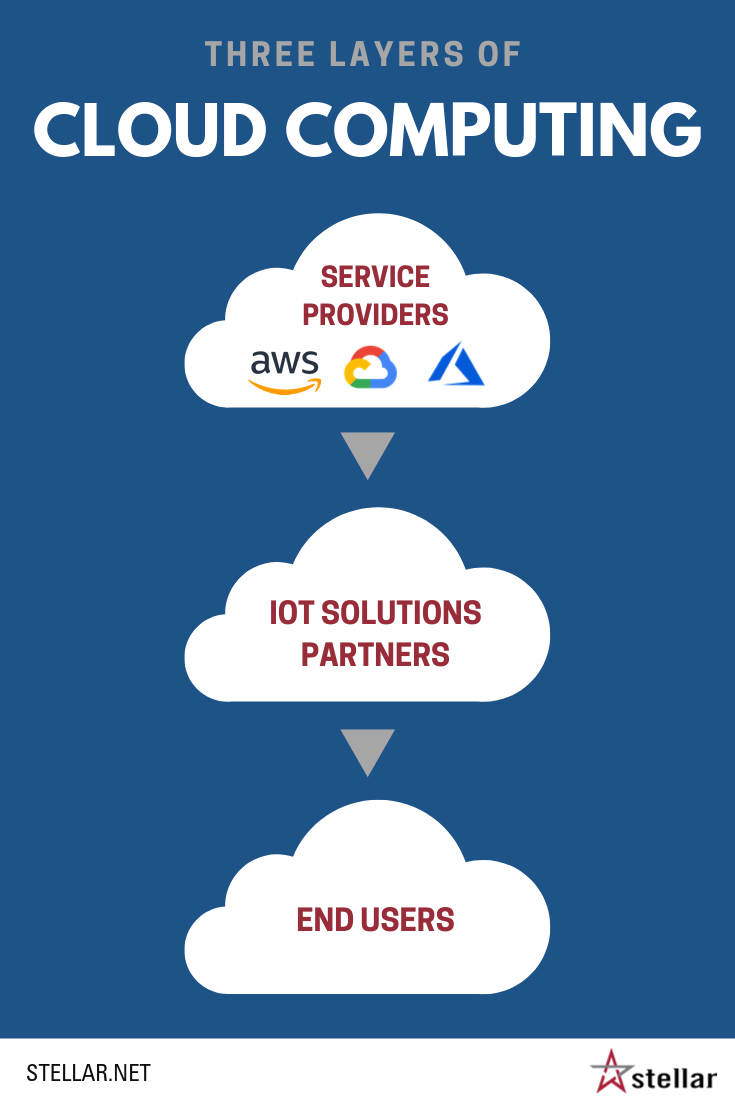

Three layers of cloud computing

When it comes to introducing machine learning to your processing, think of it as a three-tiered ecosystem:

1. Service providers (AWS, Google Cloud, Microsoft Azure)

2. IoT solutions partners (system integrators, data experts, etc.)

3. End users (Facility operator, plant owner, etc.)

Amazon Web Services, Google Cloud and Microsoft Azure are simply cloud computing service providers that can be used in a variety of applications across a variety of industries. As an end user, you wouldn’t simply call one of these companies to identify solutions for your particular facility.

That’s where an experienced IoT solutions partner comes in. At Stellar, we often advise food plants on opportunities to apply machine learning as well as which specialized software platforms are needed. These specific platforms work in conjunction with a big service provider and are tailored to niche industries and objectives.

So if you’re considering contacting an IoT partner to explore how to bring this technology to your facility, what should you do first?

Start by defining your machine learning use case

What end result are you trying to achieve? These results are the use cases for machine learning in your facility. Examples include:

- Increasing throughput

- Decreasing energy use

- Predicting equipment failure

- Maintaining air temperature efficiently

Some incorrectly assume that machine learning software can “do anything” and that artificial intelligence can “learn anything.” However, these are tools that respond to data sets and tailored logic created for a specific use case. These tools are powerful when they have a specific factor to measure, because they can recognize patterns and anomalies in data that may otherwise go undetected — but they need to be pointed in the right direction first and be given time to accumulate a large data set.

You may have several objectives you’re trying to accomplish at your facility. Each machine learning use case may require a different exploration with a different data pipeline and a different approach. And some of your objectives may not be solvable with machine learning. Give some thought to these goals before reaching out to an IoT solutions partner so you can then explore available options together.

Data exploration

The next step is collecting and understanding the data that you have available. You may have access to raw, uncategorized data produced by your facility. This is a helpful starting point. However, many food plants (old and new) don’t have the telemetry data needed to solve and understand the machine learning use case you want to solve. In this situation, your IoT partner may assist you with installing additional sensors to collect the necessary data to meet your goals.

In the case of predicting equipment failure, necessary data may include vibration in motor and compressors, amp meters, temperature and optical data, In order to truly predict anything, substantial data is needed to feed the algorithm first, which means it may take months of collection before you have enough to work with. (Note: I’m not talking about the ability for a PLC to simply provide you with a notification or update based on exactable range in a sensor — regular PLCs can already do this.)

However, your IoT solutions partner may already have numerous data sets that can help you get up and running more quickly. For example, we work with numerous companies, so we’ve amassed a significant amount of data from specific types of equipment such as screw compressors, air units and pumps. We can then use the data set Stellar has to help speed up the process of your machine learning use case.

Taking the next step

Are you curious about exploring the applications of machine learning and artificial intelligence in your facility? Gather all the information about what sensors you have, what data you have, and the accuracy and quality of the data you have and contact us.

Remember: There is no plug-and-play solution when it comes to machine learning. It requires complex work by people to teach these algorithms how to learn and become smart enough to run themselves.

If you’re ready to take that next step, email me at foodforthought@stellar.net. Have questions? Leave a comment below!