Any time you transport product from one stage of processing to another, you introduce the possibility of food safety risks. There are a variety of ways to move your product from receiving to packaging, but how do you minimize the opportunity for outside contamination during the steps between?

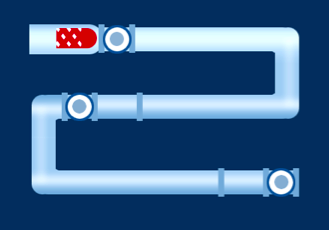

Hydrovey systems are a popular option, particularly in facilities that produce canned goods. This semi-closed-loop system transports product through piping using a stream of water and can be a safer alternative to conveyor belts. I’ve designed hydrovey systems and have seen them used in the production of several food products, including fruit, corn and beans.

While there are a number of benefits to these systems, there are important cautions to keep in mind whether you utilize them already or if you’re upgrading or designing a new facility. First, let’s explore the food safety benefits.

Food safety benefits of hydrovey systems

Hydrovey systems are typically more sanitary than conveyor belts, because they offer less opportunity for external contamination. Since the product travels through water in an enclosed pipe, it is not exposed to outside air where contaminants could be introduced from:

- Overhead walkways

- Cranes and other equipment

- Leaking overhead process lines

Since hydrovey is a semi-closed-loop system, cleaning is relatively easy as well. Introducing cleaning solutions into the system and maintaining a regular clean-in-place (CIP) schedule minimizes food safety risks in processing.

Although it’s conducive to improving your facility’s food safety, the hydrovey method only works as well as your efforts to monitor and maintain it. If you use this system in your current facility or if you’re contemplating investing in it, consider the following factors.

1. Design can make or break food safety

A poorly designed hydrovey system can negate all its inherent food safety benefits and can actually make things much worse. It’s crucial to pitch all piping at an incline in the direction of flow. This practice eliminates the chances of air pockets forming by maintaining a fully flooded piping system during operation. Piping designed in this manner not only reduces the risk of bacterial growth, but ensures full coverage cleaning.

This doesn’t just apply to new facilities, either. If you already utilize a hydrovey system in your facility, do you know if your pipes are pitched properly? Reconfiguring your design won’t only improve food safety, but it can save you money as well. Of course, you must always maintain a regular cleaning schedule, but with properly pitched pipes you may not have to clean as often as you do now to keep your system clean. This can result in cost savings by using less:

- Water

- Energy

- Cleaning solution

2. Bacterial growth is a risk

As I mentioned above, your hydrovey system can be at a greater risk for fostering bacteria if you’re not diligent with your cleaning schedule and if the system is designed poorly. If pipes aren’t pitched properly, water can sit in the pipes with exposure to oxygen — conditions ripe for organic growth.

In this scenario, you could still be at risk despite your CIP cleaning schedule — at that point flushing the line can just be a temporary bandaid on a much bigger problem. I’ve seen instances where owners had to dismantle all the piping to discover bacterial growth and clean out the entire system.

In addition to proper design, you can reduce the risk for bacterial growth by maintaining a regular CIP schedule, of course. Depending on the product you run through your piping, you may also consider taking the extra step of pigging. This is the process of pressurizing and launching a “pig” through the piping in order to clean it out. Think of this as sending a rubber, bullet-shaped pipe cleaner through to physically brush out the inside of your pipes. While this is a more expensive and detailed option, it is more effective than flushing your system with cleaning solution.

Source: PolyEurope

3. Regular maintenance and monitoring is crucial

While a hydrovey system can be more sanitary than a conveyor belt, you can’t see inside your piping with the naked eye. This means your hydrovey system needs extra attention and a diligent CIP schedule to maintain food safety and keep pipes clean, otherwise an “out of sight, out of mind” mentality could enable a food safety recall.

Your cleaning schedule depends on the size of your equipment and how often it’s used. A good practice is to tie cleaning directly to equipment that’s being used. For example, when the blancher is being cleaned, make use of that downtime to run CIP for your hydrovey piping.

Another preventative measure is to monitor your piping regularly to address hiccups before they become catastrophes. Consider installing filters and/or meters in the lines to track cleanliness. You can also analyze your water and take samples to track cleanliness. Building a database from this information can help you determine a proper cleaning schedule. Working with an experienced partner to run these analyses and create effective designs will ensure you’re achieving optimum food safety that is both cost efficient and operationally efficient.

4. Use a proper pump

A typical hydrovey system operates by collecting the product in a hopper or tank, which is connected to a centrifugal pump system that helps move the product from Point A to Point B with water. But you must ensure you’re employing the proper pump — you don’t want to feed a pump with product that the pump is going to damage. For example, I’ve designed a system for a prune-producing plant, and we had to ensure that the pumps impellers are of proper design so not to damage the more delicate prunes.

One application may require a different type of pump compared to another. Again, partnering with an experienced team who understands hydrovey systems can go a long way in ensuring you don’t encounter snags like this during the design process.

Weigh the pros and cons

Like anything, there are benefits and risks when it comes to hydrovey systems. Overall, they can be an effective, food-safe alternative for transporting your product during processing, but you must consider the needs of your plant and the maintenance required. Each system is tailored to your processing and product, but due to the nature of hydrovey, more steps may be involved before you realize you have a problem. It’s a smart option if handled properly, but it can be a food safety nightmare if not cared for properly — understand the risks as well as the benefits to make the right choice for your facility.

Have questions about hydrovey systems? Wondering if the pros outweigh the cons for your particular product and facility? I’m happy to answer your questions! Email me at foodforthought@stellar.net

Editor’s note: A version of this post first appeared in Food Manufacturing.