Hazard Analysis and Critical Control Point (HACCP) is an internationally recognized system for reducing the risk of safety hazards in food. A HACCP system requires that potential biological, chemical or physical hazards are identified and controlled at specific points in the process. Any company involved in the manufacturing, processing or handling of food products can use HACCP to improve food safety.

So how does it work? Implementing a HACCP system requires that both prerequisite programs and HACCP plans are implemented:

- Prerequisite programs are programs that are put in place in the facility to control hazards in the environment, preventing contamination of the product (see examples)

- HACCP Plans are prepared for each process or product, and identify possible hazards and controls in place to make sure the hazards are eliminated or controlled to ensure acceptable levels in the food product

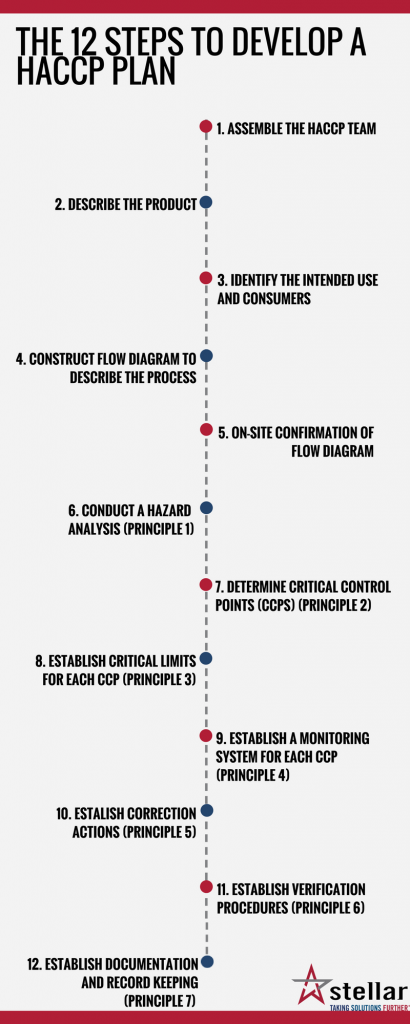

Let’s examine the steps to developing a solid HACCP plan.

1. Assemble the HACCP Team

The first step is assembling a team of individuals who have specific knowledge and expertise about the product and process. The multidisciplinary team should include individuals from departments such as:

- Engineering

- Production

- Sanitation

- Quality assurance

- Food microbiology

Don’t forget to include local personnel who are involved in the operation. The team may benefit from outside experts to weigh in on potential biological, chemical and/or physical hazards, bit these experts should serve as consultants not as a replacement for your HACCP team.

2. Describe the product

First, the HACCP team provides a general description of the food, ingredients and processing methods. Then the method of distribution should be described along with information on whether the food is to be distributed frozen, refrigerated or at ambient temperature.

3. Identify the intended use and consumers

Describe the normal expected use of the food. The intended consumers may be the general public or a particular segment of the population (e.g., infants, immunocompromised individuals, the elderly, etc.)

4. Construct flow diagram to describe the process

The flow diagram should provide a clear, simple outline of all the steps involved in the process that are directly under the control of the establishment. (The flow diagram can also include steps in the food chain which come before and after the processing that occurs in the establishment.)

The diagram can be a block-type design — it should does not need to be as complex as engineering drawings. Also, including a simple schematic of the facility can be useful for understanding product and process flow.

5. On-site confirmation of flow diagram

The HACCP team should perform an on-site review of the operation to verify the accuracy and completeness of the flow diagram, and modifications should be made to the diagram as needed. After these first five preliminary tasks have been completed, the following seven principles of HACCP are applied.

6. Conduct a hazard analysis (Principle 1)

At this point, the HACCP team conducts a hazard analysis and identifies appropriate control measures. They should list all potential hazards associated with each step. Note: A hazard is defined as a biological, chemical or physical agent that is reasonably likely to cause illness or injury in the absence of its control (i.e. safety concerns, not quality concerns).

The process of conducting a hazard analysis involves two stages:

- Hazard identification — During this “brainstorming session” stage, the HACCP team reviews the ingredients used in the product, the activities conducted at each step and the equipment used, the final product and its method of storage and distribution, and the intended use and consumers. Based on this review, the team develops a list of potential biological, chemical or physical hazards which may be introduced, increased, or controlled at each step in the production process.

- Hazard evaluation — During this stage, the HACCP team evaluates the severity and likelihood of each potential hazard occurring and decides which ones must be addressed in the HACCP plan. (Such considerations do not include common dietary choices which lie outside of HACCP.)

After completing the hazard analysis, the hazards associated with each step in the production of the food should be listed along with any measures that are used to control the hazards. The term “control measure” is used because not all hazards can be prevented, but virtually all can be controlled.

Note: More than one control measure may be required for a specific hazard, and more than one hazard may be addressed by a specific control measure (e.g., pasteurization of milk).

7. Determine critical control points (CCPs) (Principle 2)

A critical control point is defined as a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. The potential hazards that are reasonably likely to cause illness or injury in the absence of their control must be addressed in determining CCPs.

One strategy to facilitate the identification of each CCP is the use of a CCP decision tree. (Keep in mind that a decision tree is merely a tool; it is not a mandatory element of HACCP, nor is it a substitute for expert knowledge.)

Examples of CCPs may include:

- Chilling

- Thermal processing

- Product formulation control

- Testing ingredients for chemical residues

- Testing product for metal contaminants

CCPs must be carefully developed and documented. In addition, they must be used only for purposes of product safety. Different facilities preparing similar food items can differ in the hazards identified and the steps which are CCPs. This can be due to differences in each facility’s layout, equipment, selection of ingredients, processes employed, etc.

8. Establish critical limits for each CCP (Principle 3)

A critical limit is a maximum and/or minimum value to which a biological, chemical or physical parameter must be controlled at a CCP to prevent, eliminate or reduce to an acceptable level the occurrence of a food safety hazard. A critical limit is used to distinguish between safe and unsafe operating conditions at a CCP. Critical limits should not be confused with operational limits which are established for reasons other than food safety.

Each CCP will have one or more control measures to assure that the identified hazards are prevented, eliminated or reduced to acceptable levels. Each control measure has one or more associated critical limits. Critical limits may be based upon factors such as:

- Temperature

- Time

- Physical dimensions

- Humidity

- Moisture level

- Water activity

- pH

- Titratable acidity

- Salt concentration

- Available chlorine

- Viscosity

- Preservatives

- Sensory information such as aroma and visual appearance

Critical limits must be scientifically based. For each CCP, there is at least one criterion for food safety that is to be met. The critical limits and criteria for food safety may be derived from sources such as regulatory standards and guidelines, literature surveys, experimental results and experts.

9. Establish a monitoring system for each CCP (Principle 4)

Monitoring is a planned sequence of observations or measurements to assess whether a CCP is under control and to produce an accurate record for future use in verification.

Monitoring serves three main purposes:

- It facilitates tracking of the operation. If monitoring indicates that there is a trend towards loss of control, then action can be taken to bring the process back into control before a deviation from a critical limit occurs.

- It is used to determine when there is loss of control and a deviation occurs at a CCP (i.e., exceeding or not meeting a critical limit). When a deviation occurs, an appropriate corrective action must be taken.

- It provides written documentation for use in verification.

Ideally, monitoring should be continuous, which is possible with many types of physical and chemical methods. Continuous monitoring is always preferred when feasible, but monitoring equipment must be carefully calibrated for accuracy.

Assignment of the responsibility for monitoring is an important consideration for each CCP. Personnel who monitor CCPs are often associated with production (e.g., line supervisors, selected line workers and maintenance personnel) and, as required, quality control personnel. All records and documents associated with CCP monitoring should be dated and signed or initialed by the person doing the monitoring.

When it is not possible to monitor a CCP on a continuous basis, it is necessary to establish a monitoring frequency and procedure that will be reliable enough to indicate that the CCP is under control, such as statistically designed data collection or sampling systems.

10. Establish corrective actions (Principle 5)

No system is perfect, so when preventive measures fail, corrective actions must be in place to prevent potentially hazardous foods from reaching consumers. Corrective actions should:

- Determine and correct the cause of non-compliance

- Determine the disposition of non-compliant product

- Record the corrective actions that have been taken

Specific corrective actions should be developed in advance for each CCP and included in the HACCP plan. As a minimum, the HACCP plan should specify what is done when a deviation occurs, who is responsible for implementing the corrective actions and that a record will be developed and maintained of the actions taken. Individuals who have a thorough understanding of the process, product and HACCP plan should be assigned the responsibility for oversight of corrective actions.

11. Establish verification procedures (Principle 6)

Verification is defined as those activities, other than monitoring, that determine the validity of the HACCP plan and that the system is operating according to the plan.

One aspect of verification is evaluating whether the facility’s HACCP system is functioning according to the HACCP plan. An effective HACCP system requires little end-product testing, since sufficient validated safeguards are built in early in the process. Therefore, rather than relying on end-product testing, firms should rely on frequent reviews of their HACCP plan, verification that the HACCP plan is being correctly followed, and review of CCP monitoring and corrective action records.

Another important aspect of verification is the initial validation of the HACCP plan to determine that the plan is scientifically and technically sound, that all hazards have been identified and that if the HACCP plan is properly implemented these hazards will be effectively controlled.

Information needed to validate the HACCP plan often include:

- Expert advice and scientific studies

- In-plant observations, measurements and evaluations

Subsequent validations are performed and documented by a HACCP team or an independent expert as needed. For example, validations are conducted when there is an unexplained system failure; a significant product, process or packaging change occurs; or new hazards are recognized.

12. Establish documentation and record keeping (Principle 7)

Generally, the records maintained for the HACCP System should include the following:

- A summary of the hazard analysis, including the rationale for determining hazards and control measures

- The HACCP Plan

- Listing of the HACCP team and assigned responsibilities

- Description of the food, its distribution, intended use and consumer

- Verified flow diagram

- HACCP Plan Summary Table that includes information for:

- Steps in the process that are CCPs

- The hazard(s) of concern

- Critical limits

- Monitoring*

- Correction actions*

- Verification procedures and schedule*

- Record-keeping procedures*

*A brief summary of position responsible for performing the activity and the procedures and frequency should be provided

Implementing your HACCP plan

The successful implementation of a HACCP plan is facilitated by commitment from top management. The next step is to establish a plan that describes the individuals responsible for developing, implementing and maintaining the HACCP system.

Maintaining an effective HACCP system depends largely on regularly scheduled verification activities. The HACCP plan should be updated and revised as needed. An important aspect of maintaining the HACCP system is to assure that all individuals involved are properly trained so they understand their role and can effectively fulfill their responsibilities.

Note: This post is intended to provide a high-level summary of the 12 steps to developing a HACCP plan from the U.S. Food and Drug Administration. You can read the full text, complete with appendices and examples, on the FDA’s website.

Have questions about implementing your HACCP plans? Questions about food safety in your plant? Email me at foodforthought@stellar.net