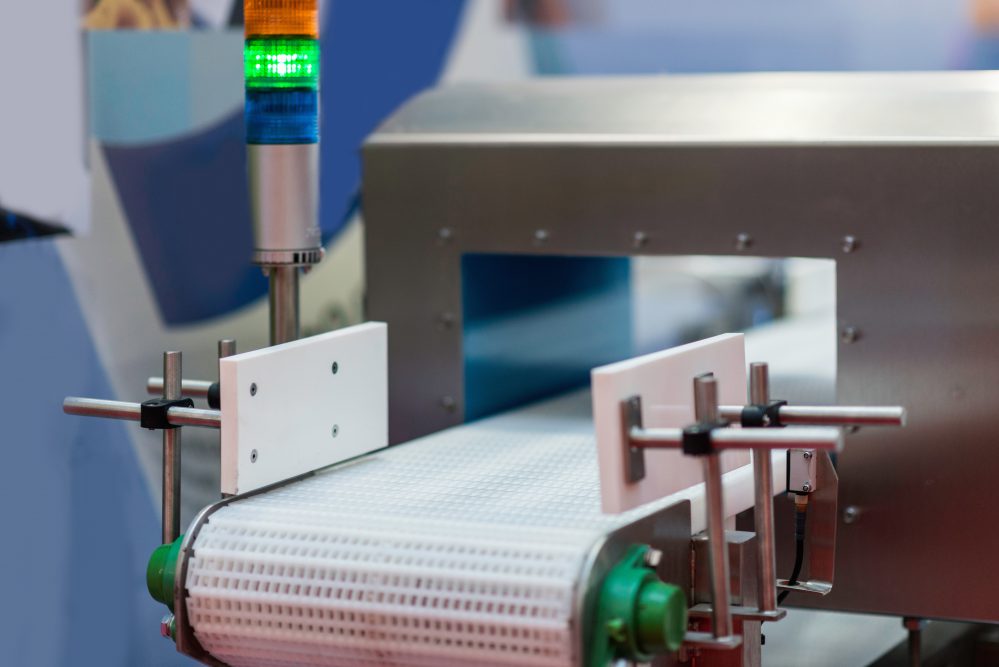

[Infographic] 7 Best Practices for Gluten-Free Manufacturing

The demand for gluten-free products isn’t just a passing trend. In fact, the gluten-free foods market is projected to be valued at $7.59 billion by 2020. Plus, researchers have noted a rise in celiac disease rates in recent years — just more evidence that the need for GF products isn’t going anywhere anytime soon. Before you begin producing gluten-free products in your facility, however, consider these principles to ensure you cater to this growing market safely, efficiently and effectively.

Continue Reading “[Infographic] 7 Best Practices for Gluten-Free Manufacturing”

![[Infographic] 7 Best Practices for Gluten-Free Manufacturing](https://stellarfoodforthought.net/wp-content/uploads/2016/10/BREAD.png)