The Advantages of Using BIM for Project Cost Estimating

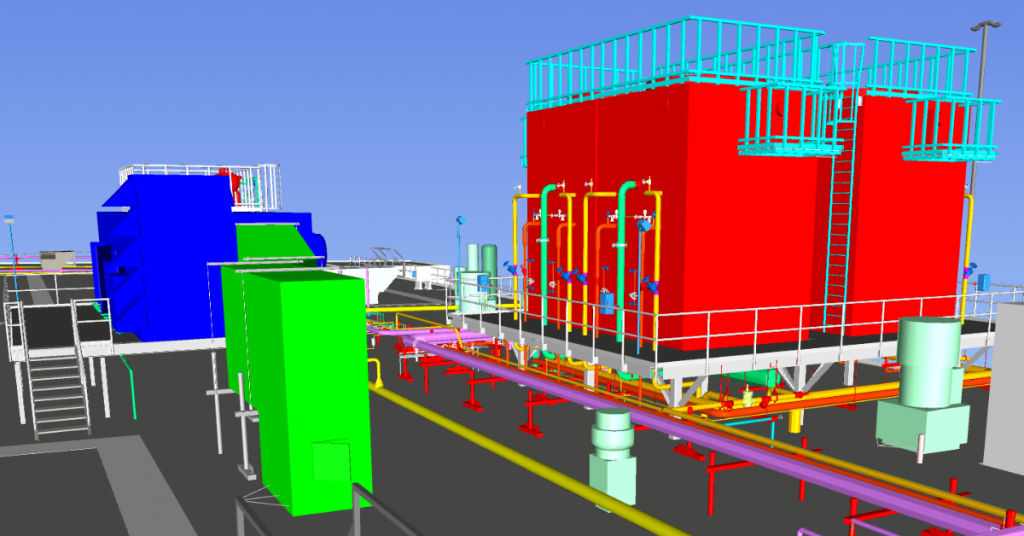

Building information modeling (BIM) technology is a revolutionary tool used by architecture, engineering and construction (AEC) professionals. It improves overall project collaboration and communication across disciplines by transforming 2D paper-and-pencil concepts into virtual 3D models that decision-makers and end-users can interact with.

When renovating or designing a new food and beverage facility, one of BIM’s most beneficial applications is its ability to define scope in detail.

It’s difficult to determine exact cost estimates early in a project due to supply chain volatility, material costs, labor wage rates, site conditions and other variables. However, BIM software’s granular capabilities can significantly improve the accuracy of those forecasts and track decision impacts throughout the process.

Continue Reading “The Advantages of Using BIM for Project Cost Estimating”