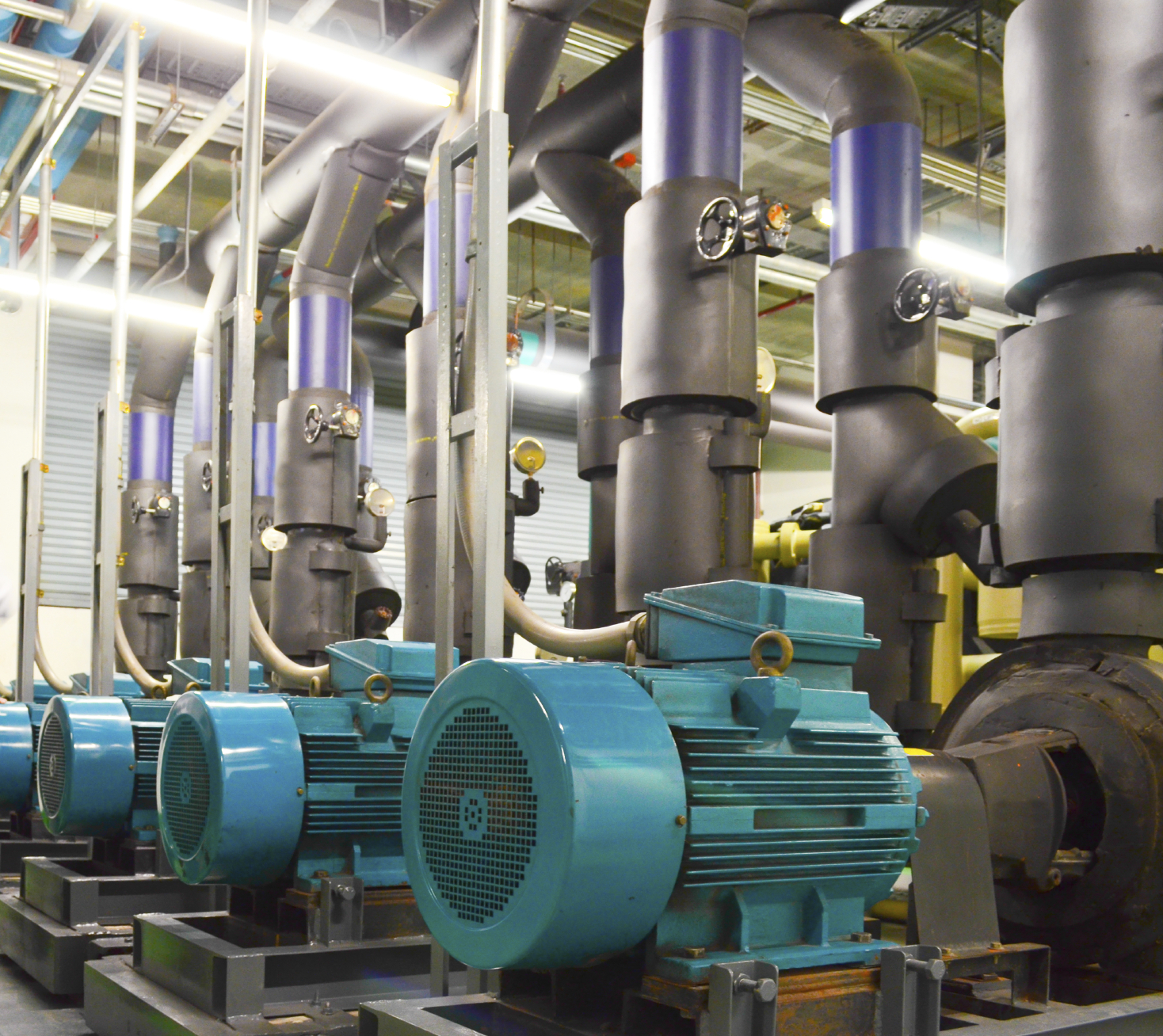

Six Factors That Can Improve Condenser Performance

As the second highest energy consuming component of your refrigeration system, condensers are also one of the most critical elements. Knowing how to optimize your condenser can increase operational performance while reducing energy usage and maintenance costs.

Continue Reading “Six Factors That Can Improve Condenser Performance”