Modern refrigeration controls systems have truly come of age. If your controls system is more than a few years old, you might be surprised at the benefits that newer systems provide:

1. Ethernet architecture — Unlike older serial networks with slower, linear structure, new control systems operate via your existing Ethernet. These networks are non-proprietary so in-house IT teams can easily troubleshoot issues, and repair and replace parts.

2. Improved compressor and VFD communications — Hard-wired serial control systems are slower to communicate with your compressors and VFDs. With an Ethernet platform, the system can pull data much quicker and more efficiently.

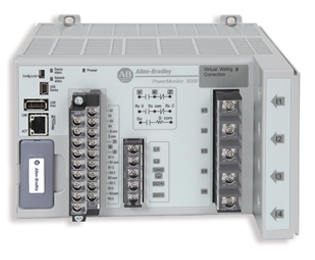

3. A single integrated platform — Old systems are often disjointed, with input/outputs, PLC hardware, VFDs, communications protocols and automation controllers all operating independently or requiring customized interfaces. Newer systems are integrated, providing you with a single, unified platform with standards-compliant methods for configuring, operating and maintaining a range of instruments and equipment.

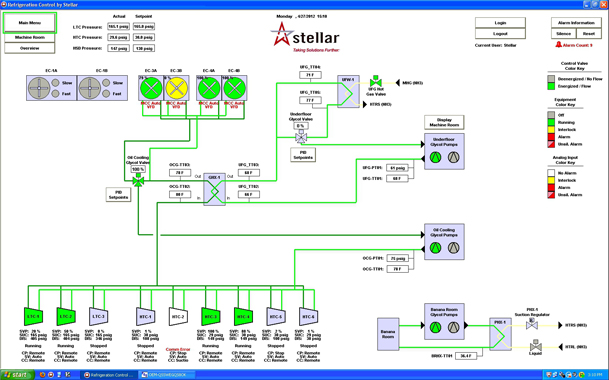

4. Increased data availability — With a single, integrated platform, you’ll have increased access to energy, production, and utility cost information, leading to better decision-making at the management level. You can generate trend analyses, alarm logs, energy management data, and runtime reports in real-time to make the necessary changes and modifications to ensure your refrigeration system is running at optimal efficiency.

Continue Reading “Benefits of Upgrading Your Refrigeration Controls”