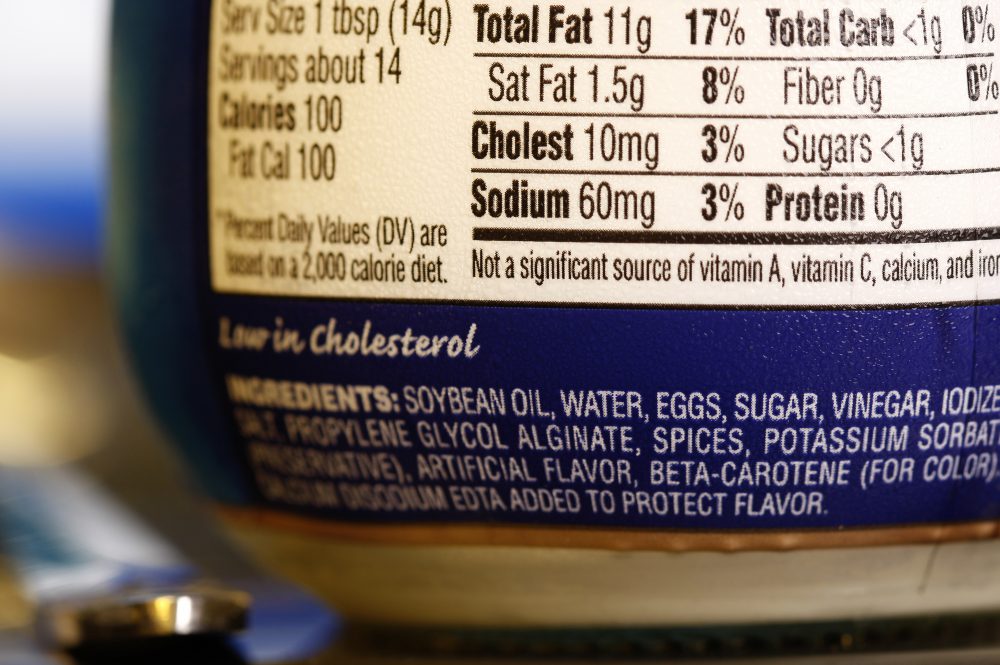

Hazard Analysis and Critical Control Point (HACCP) is an internationally recognized system for reducing the risk of safety hazards in food. A HACCP system requires that potential biological, chemical or physical hazards are identified and controlled at specific points in the process. Any company involved in the manufacturing, processing or handling of food products can use HACCP to improve food safety.

So how does it work? Implementing a HACCP system requires that both prerequisite programs and HACCP plans are implemented:

- Prerequisite programs are programs that are put in place in the facility to control hazards in the environment, preventing contamination of the product (see examples)

- HACCP Plans are prepared for each process or product, and identify possible hazards and controls in place to make sure the hazards are eliminated or controlled to ensure acceptable levels in the food product

Let’s examine the steps to developing a solid HACCP plan.

Continue Reading “The 12 Steps to Develop a HACCP Plan”

![How a Facility Assessment Helped Royal Cup Coffee Build, Expand and Renovate Efficiently [Case Study]](https://stellarfoodforthought.net/wp-content/uploads/2017/01/Screen-Shot-2017-01-25-at-10.59.02-AM.png)

![[Infographic] 7 Best Practices for Gluten-Free Manufacturing](https://stellarfoodforthought.net/wp-content/uploads/2016/10/BREAD.png)