Facilities that produce canned goods use steam and water during the canning process. But some of them are flushing potential energy savings down the drain — literally. Whether your plant manufactures canned tuna, beans or vegetables, a heat exchanger could help cut energy costs with little upfront investment.

Pre-heating water

In a typical canning facility, the product is canned, sealed and cooked by steam before being labeled and shipped. That means the facility pays for the water, pays to heat it into steam and then pays to dispose of it via wastewater fees.

But what if you could take advantage of this “wastewater” before sending it down the drain back to the city?

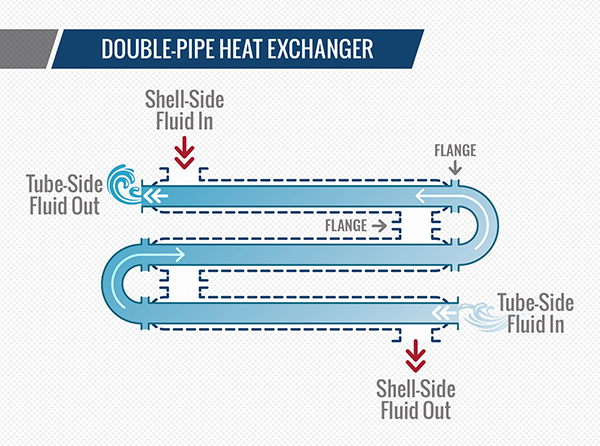

By installing a heat exchanger and some additional piping, thus recirculating the heated wastewater through the exchanger, the wastewater would pre-heat the cooler, incoming water on its way out the door. That raises the baseline temperature for the incoming water, meaning less energy spent converting it to steam. It’s essentially a free head start to the heating process.

This is a simple way to convert what would otherwise be pure waste into energy savings, without having to alter your processing.

Pre-chilling water

Of course, energy savings can also be realized in the complete inverse of this process. Some facilities must chill water for their processing, such as to wash poultry. Therefore, they pay for the water, pay refrigeration costs to lower its temperature and then pay wastewater fees to dispose of the chilled water.

By redirecting it through a heat exchanger, the outgoing chilled water can help lower the temperature of incoming city water. Again, this means less energy is spent on refrigeration to bring water all the way down to the proper temperature. And because the “clean” and “dirty” water never come into contact with each other, there’s no risk of contamination (as in the raw poultry example).

A simple, cost-effective solution

Relatively speaking, this is a simple solution that requires minimal capital investment for the ROI: All you need is the heat exchanger, additional piping, insulation and possibly a recirculating pump. Little to no additional energy needs to be applied to the process.

Of course, the ROI varies on geographic location, too. Groundwater in Florida is naturally warmer than in Tennessee, for example.

Over time, this can add up to significant savings. For example, at a facility we recently visited they were disposing roughly 300,000 gallons of heated water per day — and they’d gone for years without capitalizing on that energy opportunity. If your plant is heating or cooling water for its processing, are you taking full advantage of the energy you’re expending?

Curious how to capitalize on these savings at your facility? Email me at foodforthought@stellar.net or leave a question in the comment section below.