There has been a push to take advantage of the benefits of ammonia while reducing the risks—and it has resulted in an innovative solution: low-charge packaged refrigeration systems that use ammonia and a secondary refrigerant (such as glycol). This allows facilities to reap the benefits of ammonia’s excellent thermodynamic properties while minimizing the charge and risk.

What is a packaged refrigeration system?

This new type of system is “packaged” or “modular,” with refrigeration equipment built off site, mounted on a structural steel base, and delivered to your plant as a self-contained, “plug-and-play” system. Because it uses secondary refrigerants—which isolates ammonia to the machine room and only uses about one pound of ammonia per ton of refrigeration—it minimizes your facility’s charge.

Synthetic refrigerants are out; natural refrigerants are in

It’s no secret synthetic refrigerants are being phased out of food manufacturing facilities. Global pressure and governmental regulations are mandating all food plant manufacturers to transition to natural refrigerants—such as ammonia and CO₂.

Last year, the Environmental Protection Agency (EPA) announced the delisting of the use of:

- R134A

- R404A

- R507A

- And other hydrofluorocarbons (HFCS)

This legislation was enforced under the Significant New Alternatives Program, or SNAP. Under SNAP, each application with a delisted HFC is approved for the use of a natural refrigerant like ammonia. Exactly what lies ahead in terms of legislation and oversight has yet to be determined; however, strict regulations on the use and phaseout of high-GWP refrigerants is certain.

Cold storage facilities across the country are incorporating low-charge packaged refrigeration systems to incorporate natural refrigerants while minimizing environmental impact and increasing savings.

One such facility is Caspers Cold Storage and Distribution, a McDonald’s franchisee who worked with Stellar to design a new 116,000-square-foot facility. Caspers needed a facility that was eco-friendly and supported a new business model as the company shifted its primary focus to cold storage. “Plug-and-play” packaged refrigeration systems allowed for quick installation and reduced long-term refrigerant costs by utilizing an ammonia/ CO2 cascade system.

Low-charge systems use ammonia or CO₂ and a secondary refrigerant (such as glycol), allowing facilities to reap the benefits of ammonia’s excellent thermodynamic properties while minimizing the charge and risk.

5 benefits of packaged refrigeration systems

As your food plant phases out synthetic refrigerants, consider the below benefits of a low-charge packaged refrigeration system.

1. Enhanced safety—Secondary refrigerant systems reduce the total quantity of primary refrigerant. Ammonia is isolated to the machine room, reducing the risk to plant personnel in the event of a leak. This means that no ammonia is in the process space and ammonia detection is not required in multiple rooms. Facilities with more than 10,000 pounds of ammonia must comply with Occupational Safety and Health Administration (OSHA) rule 29 CFR, but secondary refrigeration systems use less than that amount.

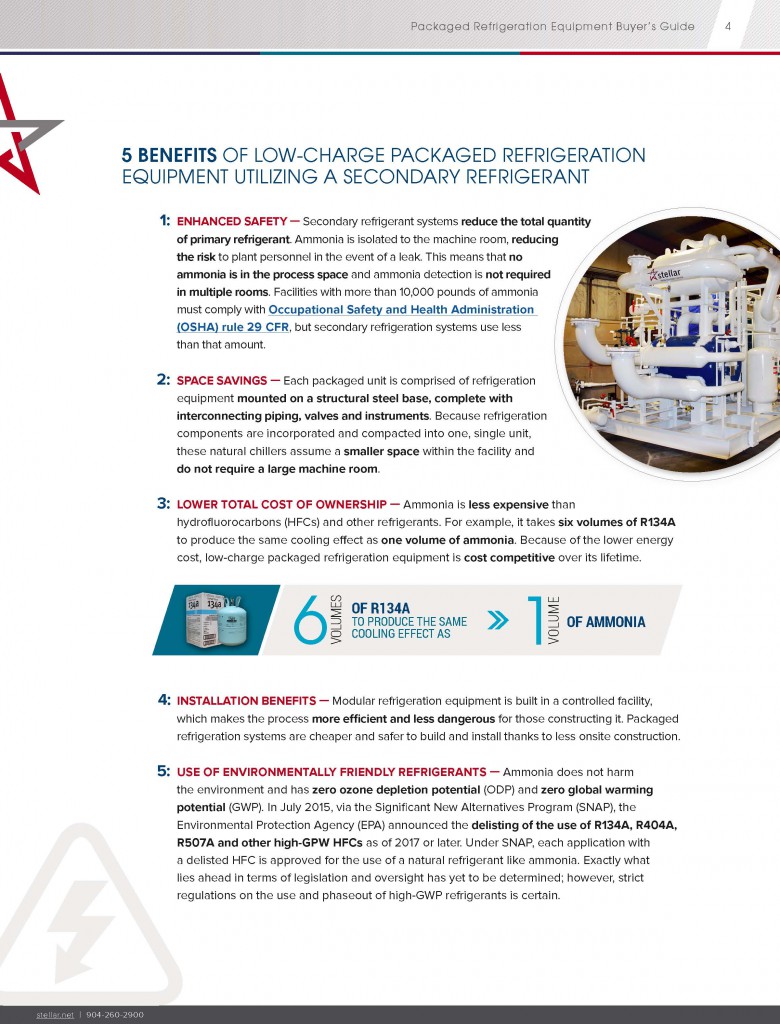

2. Space savings—Each packaged unit is comprised of refrigeration equipment mounted on a structural steel base, complete with interconnecting piping, valves and instruments. Because refrigeration components are incorporated and compacted into one, single unit, these natural chillers assume a smaller space within the facility and do not require a large machine room.

3. Lower total cost of ownership—Ammonia and CO₂ are significantly less expensive than hydrofluorocarbons (HFCs) and other refrigerants. Because of the lower energy cost, low-charge packaged refrigeration equipment is cost competitive over its lifetime.

4. Installation benefits—Modular refrigeration equipment is built in a controlled facility, which makes the process more efficient and less dangerous for those constructing it. Packaged refrigeration systems are cheaper and safer to build and install thanks to less onsite construction.

5. Use of trusted environmentally friendly refrigerants—Ammonia has been the mainstream refrigerant of choice in the food and beverage industry for 100 years. CO₂, another natural refrigerant, is found in the environment as a renewable resource. Both were used before the introduction of synthetic refrigerants, and are safe alternatives to use today.

Ammonia does not harm the environment and has zero ozone depletion potential (ODP) and zero global warming potential (GWP), and CO₂’s environmental impact as a refrigerant is insignificant. But aren’t we supposed to be reducing our use of CO₂?

The conversation surrounding the environmental impact of carbon dioxide is “strange.” Greenpeace is “arguing for the uptake of carbon dioxide in one area” while “pushing for its reduction in another.” However, CO₂ as a refrigerant is surprisingly green.

Let’s compare carbon dioxide from a car versus a refrigeration system:

- In a year’s time, a car will emit five tons of carbon dioxide.

- In a CO₂-charged refrigerator’s 10-year lifetime it will emit 300 grams.

As your food plant facility moves to updated refrigeration equipment, consider installing low-charge packaged refrigeration systems to increase safety, reduce cost and minimize environmental impact.

Editor’s Note: This post was originally published in January 2016 and has been updated to provide more relevant information.