Now that COVID-19 is a risk encountered in everyday life, food plant owners and operators are looking for ways to protect their staff and facilities that are cost-effective and don’t hinder productivity.

As scientific authorities continue to nail down exactly how COVID-19 is spread, the overwhelming evidence suggests the virus primarily travels and is transmitted through droplets in the air. That’s why shielding your facility from an outbreak starts with its HVAC and refrigeration systems.

1. Proper airflow is paramount

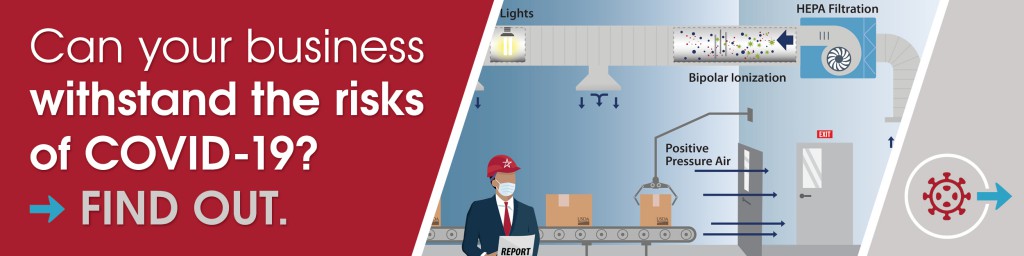

Before adding any supplemental air filtration and disinfection components, make sure your HVAC system has the correct amount of air flowing through it according to the system’s design, as well as local and state codes. Depending on your facility’s location, a specific amount of fresh air (i.e, air assumed to be free of contaminants) must be brought into a space, depending on size.

That means you should pay special attention to where air flowing into inhabited areas of your facility is drawn from — fresh air should not be pulled from storage or loading docks. Any air that is recirculated from within the facility should pass through HEPA or UV filtration (more on that shortly) to ensure it is clean before reentry.

If possible, create a positive pressure environment where workers are present to ensure air is constantly refreshed.

However, make sure to be methodical about changes to your HVAC system. Over the years, as additions are made and systems change, air flow changes. Ensure the current system is capable of moving the required amount of air through any new or upgraded components.

2. HEPA filtration

HEPA filtration systems use a fine mesh designed to capture airborne particles as air passes through them, decontaminating the air as it moves through the mesh.

Many HVAC systems designed a decade ago or earlier weren’t made with HEPA filtration in mind, so you may need to add an external filtration unit that increases surface area to your system in order for air to pass through the HEPA filter without obstructing airflow.

Keep in mind that HEPA filtration is not a one-size-fits-all solution — some systems simply can’t accommodate the addition. And for different areas of any given facility, incorporating different filtration levels may be wise.

For example, in industrial areas, you may need to incorporate stronger filters, while in a high foot-traffic area, it makes sense to have a standalone filtration system, not connected to the air conditioner, that takes advantage of already high ambient airflow.

3. UV light decontamination

While the whole spectrum of ultraviolet (UV) light has been shown to kill microorganisms, including viruses, UV-C light is the most effective. However, it can cause burns to the skin and eye damage if people are directly exposed, so UV-C light sources should be concealed.

In large HVAC systems, sections of UV-C lights can be installed in intake areas, so air is exposed to the light before going inside the unit. An external HEPA filtration box is another great place to conceal UV-C lights while taking advantage of their decontaminative properties.

4. Bipolar ionization

Bipolar ionization works by producing positively and negatively charged oxygen ions that interact with and trigger oxidation in mold, bacteria and virus cells. The positively and negatively charged particles then cluster together to be more easily caught by filters or travel more quickly to surfaces where they can be cleaned.

While it’s an effective COVID-19 mitigation tool, outfitting a large facility with adequate bipolar ionization could require the installation of many (dozens or more) ionizers and could prove to be very costly, so Stellar doesn’t utilize this technology as often as UV light and HEPA filtration.

What do I do now?

If this seems like a lot of information to process, especially when trying to apply it to your particular facility, it’s because it is.

With our deep knowledge and expertise of food plant design and HVAC and refrigeration systems, Stellar can audit your facility and provide custom-tailored COVID-19 mitigation strategies*. We can provide a proposal with recommendations for improvement and design different tiers of protection to be built-in to your systems.

Contact me at rdpeterson@stellar.net to request an evaluation of your facility and find out how you can protect your operations from airborne pathogens.

*Disclaimer: Please be advised that nothing completely eliminates bacteria or viruses and these are efforts to contain and control the spread of a virus. Stellar cannot and does not warrant or represent that every virus or microorganism will be removed, eradicated or rendered non-viable.