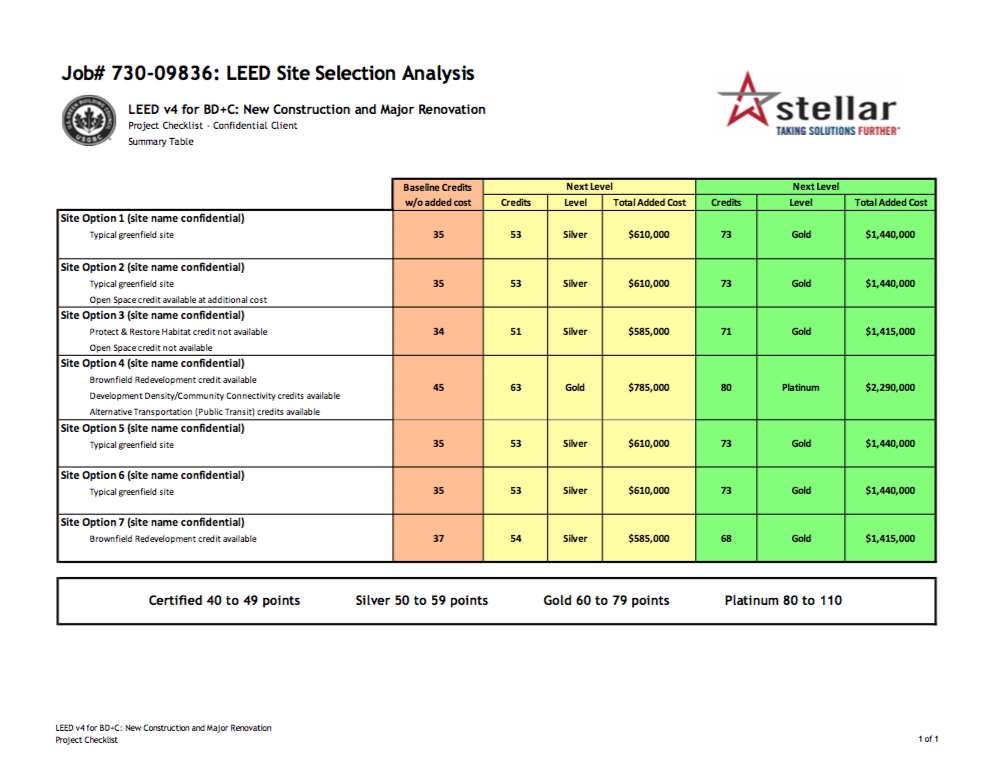

The Pros and Cons of Your Facility Location with Stricter LEED v4 Criteria

When it comes to earning LEED certification, the location of your building plays a major role. After all, site selection accounts for 26 out of a possible 110 credits under LEED v4 New Construction — that’s more than halfway to the 50 credits required to achieve LEED Silver status.

A variety of factors determine whether your site is eligible for certain credits. Many times, simply looking 10 feet beyond the city limit and into county land can make a dramatic difference in cost or eligibility to earn certain credits.

Urban sites offer many “given” points that don’t require site modifications, such as access to public transit, but property near a city center is often more expensive. On the other hand, “paid” points that involve investing in site modifications — such as Sustainable Sites credits — realistically require a larger piece of land, which is often hard to find near a downtown area.

Continue Reading “The Pros and Cons of Your Facility Location with Stricter LEED v4 Criteria”

![[Infographic] 7 Best Practices for Gluten-Free Manufacturing](https://stellarfoodforthought.net/wp-content/uploads/2016/10/BREAD.png)

![[Infographic] Installing Packaged Refrigeration vs. Traditional Systems](https://stellarfoodforthought.net/wp-content/uploads/2018/02/Packaged-refrigeration.png)