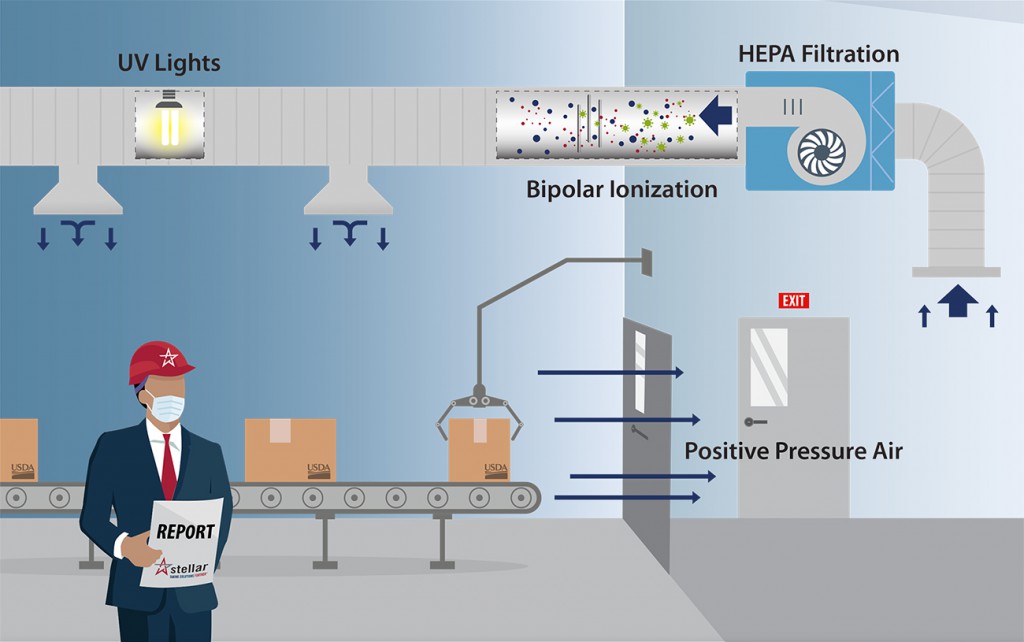

Proper Air Balance is Critical to Employee Wellbeing and Food Safety

Proper air balance in a food plant is required to maintain the environmental parameters that keep the space food-safe, including temperature, humidity and the frequency of air replacement. Additionally, the direction of airflow is important, especially when dealing with raw animal products.

Now, in the post-pandemic world, clean, fresh air is more valuable than ever. As the world gets back to work, it’s important to examine your facility’s air system to ensure it’s up to par to keep workers and consumers safe.

Continue Reading “Proper Air Balance is Critical to Employee Wellbeing and Food Safety”

![Prepare Your Food Plant for a Hurricane [Infographic]](https://stellarfoodforthought.net/wp-content/uploads/2015/10/Untitled-design.png)

![Installing Packaged Refrigeration vs. Traditional Systems [Infographic]](https://stellarfoodforthought.net/wp-content/uploads/2018/08/083018_Feature-image.png)

![[Infographic] Installing Packaged Refrigeration vs. Traditional Systems](https://stellarfoodforthought.net/wp-content/uploads/2018/02/Packaged-refrigeration.png)