How Stocking Up (or Not) on Spare Refrigeration Parts Can Impact IIAR 6 Compliance

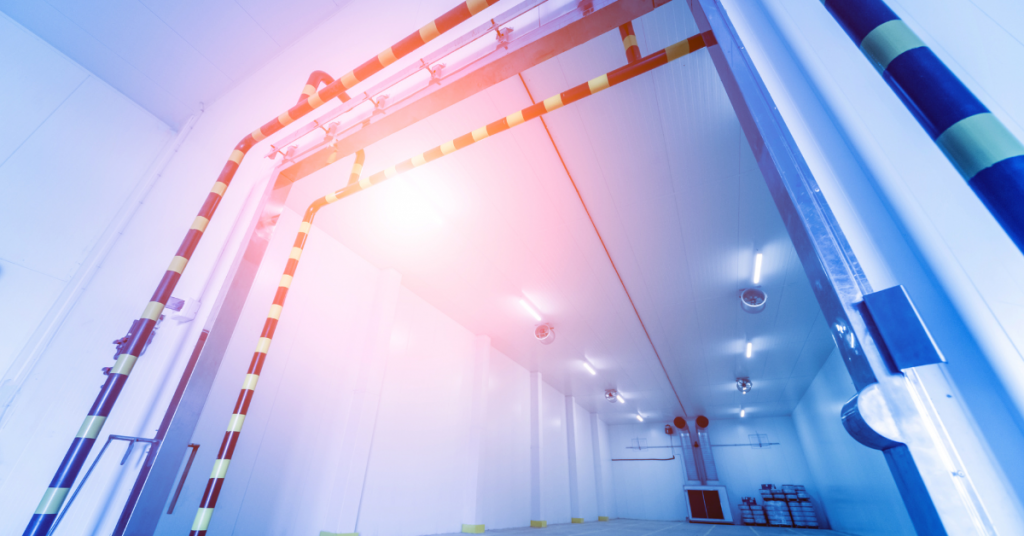

When using ammonia refrigeration in a facility of any kind — whether it be meat or poultry processing, frozen food production or cold storage — compliance with ammonia safety standards is a must.

The International Institute of Ammonia Refrigeration (IIAR) is a membership-based technical society focused on ammonia refrigeration advocacy, education and standards. As an accredited American National Standards Institute (ANSI) Developer, IIAR establishes the minimum requirements for safely inspecting, testing and maintaining closed-circuit ammonia refrigeration systems.

Continue Reading “How Stocking Up (or Not) on Spare Refrigeration Parts Can Impact IIAR 6 Compliance”