Construction Labor Costs: 4 Ways to Avoid Budget Surprises in 2019

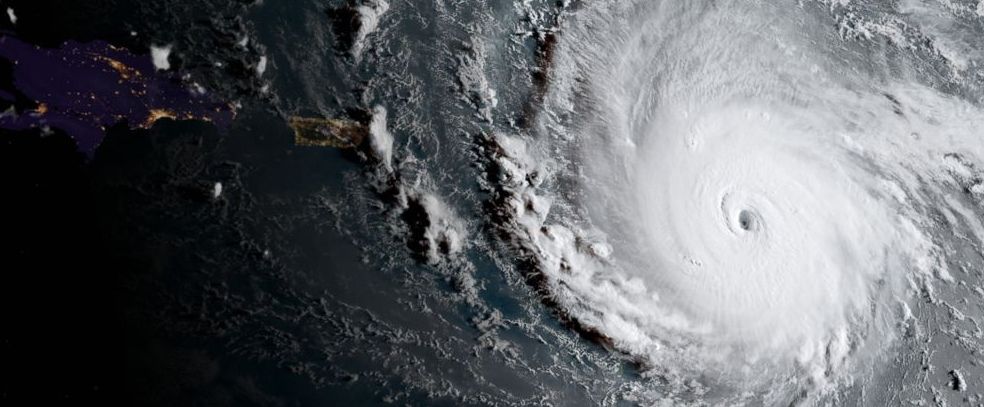

Photo by Matt Harding, Yuma Sun

As the economy thrives and capital investment grows, the construction market continues to face a labor shortage in 2019. This can especially be a factor when it comes to skilled labor for specialized disciplines, such as refrigeration.

What does this mean for food and beverage companies looking to build or expand? If it’s been a few years since your business has tackled a large capital investment project, you’ll need to manage expectations and plan accordingly. Today’s economy is a different playing field with different challenges.

If you’re planning to invest in a new facility, renovation or expansion, here are four things you can do to avoid budget surprises along the way.

Continue Reading “Construction Labor Costs: 4 Ways to Avoid Budget Surprises in 2019”