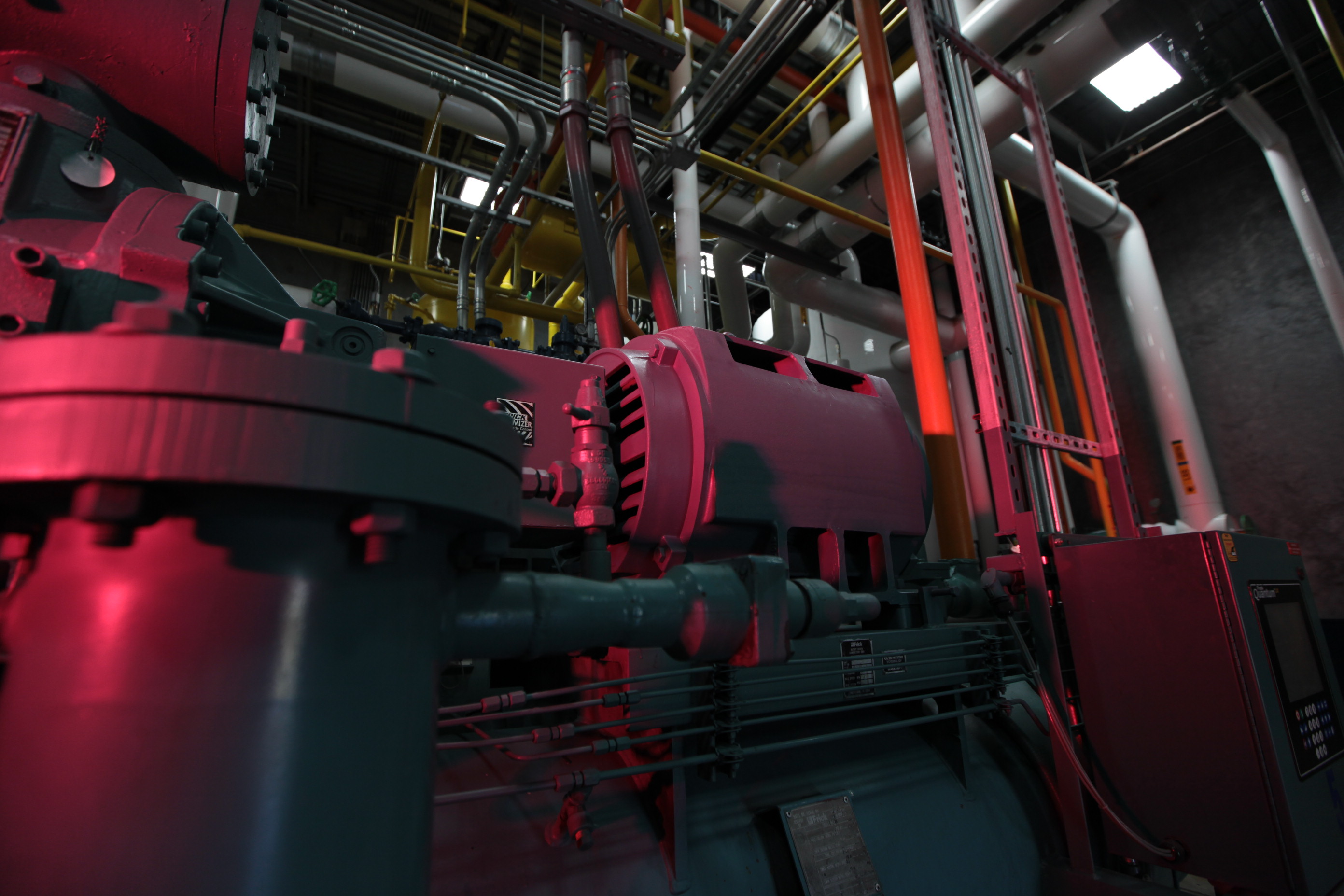

Hog Chilling: Why Quick Chill Systems are Worth the Investment

There are more than 68,000 pork producers in the United States alone—competition is fierce. So how can your hog facility remain competitive? By producing the highest quality product possible for consumers, efficiently. And an effective chilling system is key to facilitating the most premium product for your consumers: a flavorful cut of meat with appealing color, firmness and moisture levels. The faster a carcass is cooled after slaughter, the better quality the meat will be. Quick chill systems, specifically, reduce chill time and produce a better cut of meat. While they may be a significant upfront investment for your food plant, this method offers significant advantages and long-term ROI.

Continue Reading “Hog Chilling: Why Quick Chill Systems are Worth the Investment”

![[Infographic] 5 Important Factors for Selecting a Site for Your New Food Plant](https://stellarfoodforthought.net/wp-content/uploads/2016/03/5-FACTORS-FOR-FOOD-PLANT-SITE-SELECTION.png)

![[Infographic] 4 Steps in Developing a Manufacturing Plan](https://stellarfoodforthought.net/wp-content/uploads/2015/10/4-steps-in-developing-a-manufacturing-plan.jpg)