Wraparound or RSC Packaging? How Case Design Can Impact Your Bottom Line

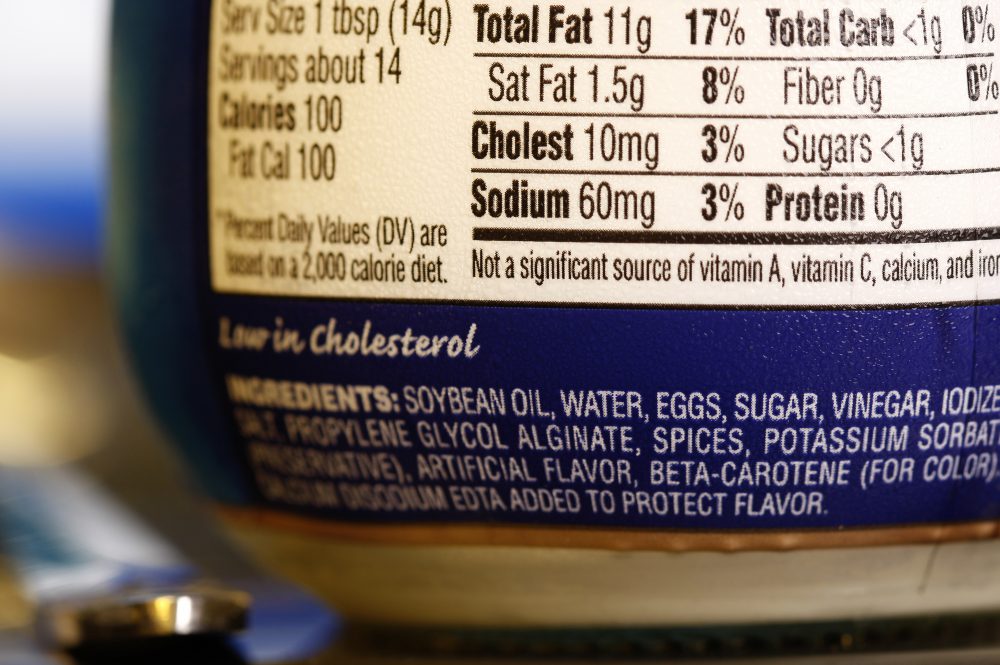

The accelerated expansion of e-commerce over the past five years paired with ongoing supply chain constraints have affected a crucial area of food and beverage processing: packaging.

The price of corrugated has been steadily increasing for years, but recent data from the Bureau of Labor Statistics reveals a sharp spike in cost since the onset of the COVID-19 pandemic. The cost of corrugated and solid fiber box manufacturing products reached an all-time high in February 2022.

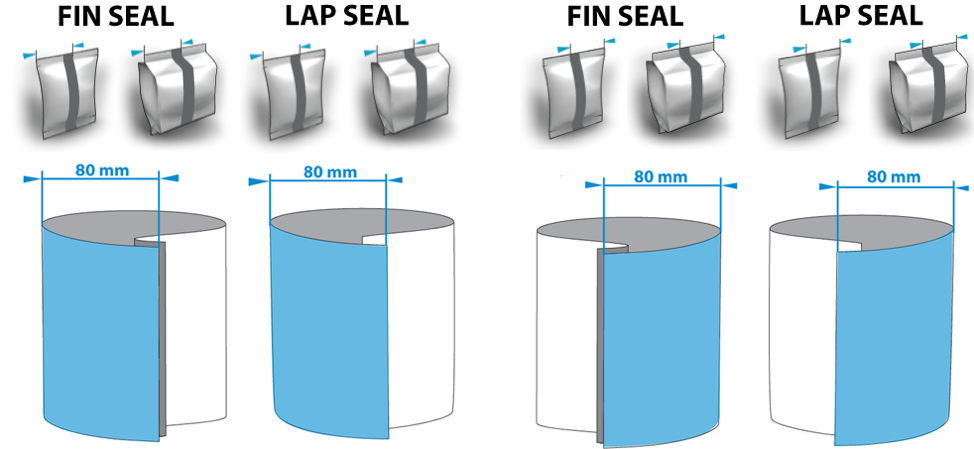

In the face of significant price increases, owners must be strategic and intentional with material purchases and investments. This is the perfect time to reevaluate your facility’s current packaging process, including whether a change in case style could help optimize your process and save money.

Continue Reading “Wraparound or RSC Packaging? How Case Design Can Impact Your Bottom Line”